We value our partnerships with the media and welcome any inquiries about the ACG Group. Please use the resources on this page, or if you have any specific queries please reach out to the media contact listed below.

ACG launches DryPod™ – A Breakthrough Desiccant-Based Cold-Form Laminate Delivering Superior Protection for Moisture-Sensitive Pharmaceutical Blisters at PMEC 2025

ACG, the world’s most integrated provider of solid-dosage and packaging solutions, today announced the launch of DryPod™, a next-generation desiccant-based cold-form laminate engineered to protect highly moisture-sensitive drug molecules. DryPod™ marks a major advancement for pharmaceutical manufacturers who have long grappled with limited availability, rigid technologies, and compatibility issues within existing desiccant cold-form solutions.Moisture protection is essential to ensure drug potency throughout the product’s retail life. However, current market offerings rely heavily on a single patented co-extrusion-based technology, creating challenges such as restricted machine compatibility, dependence on specific lidding foils, long lead times, limited supplier options, and inconsistent on-ground technical support. DryPod™ overcomes these barriers, giving pharmaceutical companies the freedom to innovate without compromising product protection, regulatory compliance, or operational efficiency.Unlike legacy co-extruded structures, DryPod™ is built using a proprietary lamination-based approach, enabling consistent performance across all standard blister-forming technologies. This eliminates the need for specialised retrofits or process changes and gives manufacturers complete flexibility to run DryPod™ on their existing blister lines. The laminate can also be sealed with any PE-sealable lidding foil, reducing procurement dependencies and ensuring supply-chain agility across global operations.A significant differentiator for DryPod™ is its patent-clean design. Engineered with zero overlap with existing active patents in the desiccant co-extrusion space, DryPod™ offers pharmaceutical companies complete legal clarity and peace of mind when switching suppliers, scaling production, or expanding into new markets. This removes a longstanding barrier for companies seeking secure, long-term, and globally compliant moisture-protection solutions.DryPod™ is supported by ACG’s extensive global technical service network, ensuring smooth onboarding, rapid troubleshooting, and optimised packaging performance across diverse manufacturing environments. With its advanced protection capabilities and universal compatibility, DryPod™ represents a future-ready solution for safeguarding highly moisture-sensitive molecules.“DryPod™ is built for the realities of modern pharmaceutical manufacturing,” said Dr. Akbar Ali, General Manager and Head of Development and Technologies at ACG. “Manufacturers working with moisture-sensitive molecules have faced years of constraints due to rigid technologies and supply limitations. DryPod™ directly addresses these challenges, empowering innovators to bring critical therapies to market more efficiently and reliably.”With this launch, ACG strengthens its commitment to making global pharmaceutical manufacturing safer, smarter, and more flexible. DryPod™ is now commercially available worldwide.About ACGFor over 60 plus years, ACG has been innovating the production solutions for pharmaceutical and nutraceutical companies, that help make people better. As the world’s most integrated provider of oral dosage products and services, we produce capsules, barrier packaging materials, manufacturing machinery, and visual inspection and traceability solutions. All fully compliant with international standards. Today, ACG fosters long-term collaborative partnerships with customers in 138 countries across six continents. Together, we share a common purpose: to solve the world’s greatest health challenges and make it better for everybody we serve. For more information, please contact the ACG media relations team: madhurima.chakraborty@acg-world.com

Read more

ACG wins Red Dot Design Award for Personalised Medicine Concept

ACG, the world’s most integrated provider of solid-dosage solutions, is proud to announce that its Personalised Medicine Concept (PMC) has been awarded the prestigious Red Dot Award for high design quality in the Medical Devices and Technology category. The Red Dot is an internationally recognised symbol of design excellence, awarded only to concepts that demonstrate exceptional creativity and innovation.The PMC reflects the strength of the OneACG ecosystem, bringing together expertise from ACG Capsules, ACG Engineering, ACG’s global research and development centres (Scitech India and Europe), and Vantage Nutrition, an ACG group company. This collaboration unites cutting-edge capabilities in capsule and beadlet technology, precision engineering, and digital systems to deliver a fully integrated, intelligent OSD (oral solid dosage) manufacturing solution - from development through to delivery.The Personalised Medicine Concept represents a groundbreaking advancement in personalised nutrition and medicine. By addressing the limitations of the traditional one-size-fits-all approach, the PMC enables the production of tailor-made capsules. Each batch features a unique combination and dosage of ingredients, ensuring precision, safety, and efficacy-while minimising the risks of over or under-dosing typically associated with generic prescriptions.Developed independently by ACG’s R&D teams, the PMC underwent extensive prototyping and validation. Select partners were invited to experience the technology first-hand, following which ACG entered an exclusive collaboration with Art of You (AOY) for the European market. This partnership brings together ACG’s engineering excellence with AOY’s pioneering approach to personalised supplement development.Karan Singh, Managing Director at ACG, said: “We are honoured to receive the Red Dot recognition. In the healthcare sector, everyone talks about personalisation. Few can manufacture it. That’s what makes this moment different. Our engineers, scientists, and nutrition experts have built an end‑to‑end capsule platform that can read a person’s health profile and deliver the exact combination and dose – reliably and at scale. Red Dot recognises the design quality; I am proud of ACG’s discipline and grit in making personalisation a reality”Pablo Smolders, Founder at Art of You, added “We’re proud to collaborate with ACG in bringing the PMC to life - setting a new benchmark for fully personalised, capsule-based supplements across Europe. This achievement highlights the incredible dedication and innovation that went into developing a pharmacy-grade machine designed specifically for personalised health and wellness.”Werner Bongers, CEO of Scitech, concluded “The PMC is a testament to what OneACG stands for- seamless collaboration, smart integration, and a shared vision for the future of health. As ACG’s R&D centre, Scitech leads innovation from concept to creation, and this award reinforces our belief that purposeful design can transform the future of personalised medicine.”About ACGFor 65 years, ACG has been innovating production solutions for pharmaceutical and nutraceutical companies that help make people better. As the world’s most integrated provider of oral-dosage products and services, we produce capsules, barrier packaging materials, manufacturing machinery, and visual inspection and traceability solutions, all fully compliant with international standards. Today, ACG partners with customers in 138 countries across six continents. Together, we share a common purpose: to solve the world’s greatest health challenges and make it better for everyone we serve.Media contact:ACG Media Relations - madhurima.chakraborty@acg-world.com

Read more

ACG to invest $200 million in U.S. hard-shell capsule manufacturing

Dedicated facilities for gelatin and HPMC; 200+ jobs; operations targeted for early 2027; expands ACG’s 25-year U.S. presenceACG, the world’s most integrated provider of solid-dosage solutions, today announced a $200 million phased investment to establish its first empty-capsule manufacturing operations in the United States. The initial $100 million will fund a state-of-the-art hard-shell capsule facility in Atlanta, Georgia, with a second phase of $100 million planned to expand capacity and capabilities in the region. The investment is expected to create more than 200 jobs, with operations targeted to begin in early 2027.“ACG has served North America for over 25 years. This facility strengthens our ties with customers across the region—bringing us closer to them, enabling faster lead times, higher-quality service, and a more resilient, de-risked supply chain. Just as importantly, it lets us respond more quickly and co-develop new innovations through tighter R&D partnerships. It’s been a long time coming, and we’re glad to say it’s here,” said Karan Singh, Managing Director, ACG.ACG will establish dedicated facilities to manufacture gelatin and vegetarian (HPMC) hard-shell capsules, designed and operated to the highest global standards of quality, safety, and regulatory compliance. The program advances ACG’s Make it Better commitment and complements the company’s U.S. ecosystem spanning capsules, barrier packaging materials, processing and encapsulation machinery, visual inspection, and traceability solutions—supported by nationwide sales and service.“Atlanta is the right location to execute at scale,” said Selwyn Noronha, CEO, ACG Capsules. “Georgia and the City of Atlanta offer a pro-business environment, a strong talent pipeline, world-class connectivity, and reliable infrastructure. Combined with ACG’s recent facility builds in Aurangabad (HPMC), Thailand (gelatin), and expansions in Brazil, Croatia and India, we have the operating discipline to begin production quickly and deliver reliable supply for North American customers.”ACG has operated in the United States for more than 25 years, with North American headquarters in Piscataway, N.J., manufacturing liquid fill capsules in Chadds Ford, Pa., with several warehouses across the United States, and sales and service teams nationwide.About ACGFor 65 years, ACG has been innovating production solutions for pharmaceutical and nutraceutical companies that help make people better. As the world’s most integrated provider of oral-dosage products and services, we produce capsules, barrier packaging materials, manufacturing machinery, and visual inspection and traceability solutions, all fully compliant with international standards. Today, ACG partners with customers in 138 countries across six continents. Together, we share a common purpose: to solve the world’s greatest health challenges and make it better for everyone we serve.

Read more

Exclusive: ACG welcomes EC decision on titanium dioxide in pharmaceuticals

ACG, the world’s largest integrated supplier of pharmaceutical capsules and allied solutions, welcomes the European Commission’s recent announcement allowing the continued use of titanium dioxide in medicinal products.ACG has been deeply involved with this matter since the very inception of the concern, working on two fronts.On one side, the company has invested in the development of TiO2-free alternatives to support customer needs.On the other, ACG has played a key role in educating the global pharmaceutical community about the scientific possibilities and limitations in addressing the challenge.ACG is proud to have actively co-operated with the IQ Consortium, comprising 21 multinational pharmaceutical companies, in the creation of a robust database on the potential impact of a ban on TiO₂ in medicines.This scientific body of evidence played a vital role in informing the European Commission’s decision-making process.“This is a wise and pragmatic decision for the pharmaceutical sector,” said Dr Subhashis Chakraborty, General Manager, Head, Global Product Management at ACG Capsules.“And as the ongoing ban remains in place for the nutraceutical industry, we remain fully committed to supporting through innovative TiO₂-free capsule solutions.”Talking exclusively to NBR, Dr Subhashis Chakraborty (pictured) added: When the regulation on TiO₂ was first announced, it created significant uncertainty across the industry.ACG responded swiftly and responsibly, taking the time to understand the challenge in depth. Rather than taking advantage of the situation, we chose to proactively share the technical limitations and complexities associated with finding viable TiO₂-free alternatives.We made it very clear to our customers that an exact replacement for TiO₂, particularly to achieve white colour options, would not be possible with the current material science."This helped to set realistic expectations and prevent unnecessary reformulation risks."Our transparent communication enabled pharmaceutical companies, including the IQ Consortium, to make informed and strategic decisions, rather than operating in the dark.In doing so, we represented ourselves not only as market leaders but also as thought leaders, guiding the industry with expertise and insight, rather than simply responding to regulatory changes.In addition, while the regulatory changes originated in Europe, ACG also emphasised the broader global implications, especially for multinational corporations.We advised that organisations with global operations should remain aligned and proactively plan for potential ripple effects beyond the EU.As part of our commitment to supporting the industry, ACG has hosted multiple global knowledge-sharing sessions, including webinars, technical roundtables and direct consultations.These efforts continue to guide and educate the pharmaceutical community on both the regulatory landscape and the path forward for TiO₂-free innovations.

Read more

India's Basketball Revolution Begins: ACG launches India's First Professional Basketball League in association with BFI

Mumbai, June 6, 2025: Marking a transformative moment for Indian sports, ACG Sports Private Limited, has announced the launch of India’s first professional basketball league in association with the Basketball Federation of India (BFI). This groundbreaking initiative will feature structured competitive league in 5x5 and 3x3 formats for both men and women, establishing a comprehensive professional ecosystem that opens the door for athletes across the country to pursue basketball as a viable career.Designed to redefine how the sport is played, experienced, and supported in India, the league aims to shift basketball from a niche discipline into a mainstream pursuit. It will serve as a long-term catalyst for India’s presence on the global basketball stage, backed by world-class infrastructure, holistic athlete development, and robust community engagement.The league is being driven by ACG Sports Pvt. Ltd., a division of ACG, a global leader in integrated manufacturing solutions for the pharmaceutical and nutraceutical industries. Leveraging ACG’s deep-rooted commitment to societal advancement, this initiative represents a natural extension of its decade-long investment in grassroots basketball programs.To guide the league’s global strategy and operations, Mr. Jeremy Loeliger, Former CEO & Commissioner of Australia’s National Basketball League (NBL), has been appointed Director of ACG Sports. In his new role, Loeliger will lead the development of the league’s blueprint, bringing international standards of governance, competition, and commercial innovation to the Indian shores.“Basketball represents more than just a sport – it is a vehicle for building character, leadership, and opportunity," said Mr. Karan Singh, Managing Director of ACG. "Our decade-long journey, beginning with grassroots initiatives has focused on systematically making basketball accessible across India while building the professional pathways that young athletes need to thrive."He further added, "Our vision for this professional basketball league is to establish a self-sustaining ecosystem where every child with passion and talent can see a viable future in basketball in India. We're grateful for the partnership with BFI in making this dream a reality. While this is a commendable first step, we know that building a thriving basketball ecosystem will require sustained effort and collective support to reach its full potential.”ACG’s leadership role in this initiative goes far beyond league operations. As part of its long-term strategy, ACG will launch India’s first fully residential high-performance centre within the year. The academy will feature world-class facilities, attract top coaching talent from the U.S. and Australia, and offer comprehensive training programmes for players, coaches, and referees. Nutrition, mental wellness, and academic balance will be integral to the curriculum – ensuring holistic development of future stars.Mr. Aadhav Arjuna, President of the Basketball Federation of India, stated: “This partnership with ACG is unlike anything we’ve seen before. It is driven by vision, structured for long-term impact, and rooted in a clear understanding of what Indian basketball truly needs. We’re building not just visibility, but real momentum and global credibility. Our vision is to win medals at the Asian Games and Olympics”Mr. Kulvinder Singh Gill, Secretary General of the Basketball Federation of India, stated: “This league will unlock new opportunities for young Indian talent to grow, compete professionally, and gain invaluable exposure alongside international players and coaches.”The complete league framework including team structures, competition formats, player eligibility, and governance models – is currently in development with input from global basketball experts and key industry stakeholders. Detailed announcements on participation guidelines, venue requirements, and operational protocols will follow in a phased rollout.In the coming months, the newly formed League Council will begin overseeing standards and operations, while nationwide scouting initiatives, customised athlete development tracks, and dynamic fan engagement programs will begin laying the foundation for a vibrant, inclusive, and commercially sustainable basketball culture in India.About Basketball Federation of India (BFI)The Basketball Federation of India (BFI) is the governing and controlling body of basketball in India. It is responsible for the development and promotion of the sports at all levels. BFI manages all the national-level basketball operations in India.First national level tournaments were organized in India in 1934. The India national basketball team became a member of FIBA in 1936. The governing body, BFI, was formed in 1950. Mr. Aadhav Arjuna is the President of Basketball Federation of India.About ACGFor over 60 plus years, ACG has been innovating the production solutions for pharmaceutical and nutraceutical companies, that help make people better.As the world’s most integrated provider of oral dosage products and services, we produce capsules, barrier packaging materials, manufacturing machinery, and visual inspection and traceability solutions. All fully compliant with international standards.Today, ACG fosters long-term collaborative partnerships with customers in 138 countries across six continents.Together, we share a common purpose: to solve the world’s greatest health challenges and make it better for everybody we serve.ACG Sports Private Limited is a wholly owned subsidiary of ACG, and while it operates in a different sector, it is firmly grounded in the same institutional principles of precision, scalability, and long-term value creation.For more information, please contact the ACG media relations team:madhurima.chakraborty@acg-world.com

Read more

ACG Packaging Materials GHG Commitment Validated and Approved by SBTi

ACG Packaging Materials, a leading global supplier of integrated manufacturing solutions for the pharmaceutical and nutraceutical industries, has taken a significant step forward in its sustainability journey as the Science Based Targets initiative (SBTi) officially validated the company’s greenhouse gas (GHG) emission reduction targets. This validation aligns with ACG’s core philosophy of Making it Better, reinforcing its commitment to impactful progress toward a sustainable future.ACG Packaging Materials has committed to reducing absolute Scope 1 and 2 GHG emissions by 90%. The company has also committed to reducing Scope 3 GHG emissions from purchased goods and services, fuel and energy-related activities, and upstream transportation and distribution by 97% per tonne of products produced within the same timeframe.Speaking on this milestone, Karan Singh, Managing Director of ACG, said, “At ACG, we recognise that the future of the pharmaceutical and nutraceutical industries depends on our ability to innovate responsibly and operate sustainably. This validation provides us with a clear, science-backed framework to drive meaningful progress in reducing our environmental impact. As we move forward, our focus will be on integrating sustainable practices across our operations, investing in advanced technologies, and collaborating with stakeholders to build a resilient, low-carbon future. This milestone is a testament to our dedication to making it better while ensuring that our industry remains aligned with global climate goals”Mr. Shivshankar S.R, CEO of ACG Packaging Materials, “The SBTi validation solidifies our commitment to a business model that thrives in a carbon-conscious future. We're not simply aiming for incremental improvements; we're undertaking a fundamental shift in how we operate. Our ambitious interim targets—reducing absolute Scope 1 and 2 emissions by 54.6% and Scope 3 emissions by 61.07% per tonne of products by FY2033—demonstrate our dedication to tangible progress. This commitment enhances our ability to attract sustainability-focused investors, fortifies our supply chain, and establishes ACG as a leader in responsible manufacturing”Sunil Kumar, Head of CSR and Sustainability at ACG said, “This validation is a testament to our unwavering commitment to environmental stewardship and social responsibility. At ACG, we believe that business success is intrinsically linked to the well-being of our planet and communities. Our focus now is on expanding our sustainability initiatives beyond our operations, engaging our employees, and partnering with local communities to create a lasting positive impact. We are dedicated to building a more sustainable and equitable future for all”The Science Based Targets initiative (SBTi), a collaboration between the Carbon Disclosure Project (CDP), United Nations Global Compact (UNGC), World Resources Institute (WRI), and Worldwide Fund (WWF), provides a globally recognized framework for companies to set GHG reduction targets aligned with climate science. It specifies how much and how quickly emissions must be reduced to limit global warming to well below 1.5°C above pre-industrial levels.

Read more

ACG to boost Mexico presence with appointment of Jessica Alfaro

ACG Engineering, a division of ACG, the world's only integrated pharmaceutical solutions and manufacturing company, is delighted to announce the appointment of Jessica Alfaro as territory sales manager for the Mexico region, as the company seeks to vastly increase its presence in the territory. In her new role, Jessica Alfaro will be responsible for promoting ACG’s portfolio of process and packaging machinery in Mexico, establishing new bonds with customers through the commitment of providing integral solutions to improve their processes. With a passion for engineering, Jessica previously worked as a sales engineer for Nicolás, Sven, Pacheco Y Andresen, Design and Engineering. Her responsibilities included the monitoring of technical specifications and industry standards, as well as the continuous development of the overall product offering. She also led board sessions, assigning requirements to valid use cases that highlighted the capabilities of the product. In addition, she worked closely with customers and the engineering team to determine the needs of the process and the requirements of the system. Commenting on the appointment, John Carey, vice-president of Sales at ACG Engineering, said: “We’re delighted to welcome Jessica into this pivotal new role. ACG is currently placing real focus and investment in the Mexico region for our process and packing machinery supporting both pharmaceutical and nutraceutical manufacturers with state-of-the-art technologies. We believe her experience and dedication will play a key part in building strong customer relations in the area.”Jessica Alfaro added: “I am delighted to be joining ACG, and embracing the challenges associated with gaining a deep understanding of our clients and providing them with the best solutions to help drive their business success. “I am excited by the idea of applying my analytical skills to design efficient and sustainable processes. My chemical engineering background gives me the opportunity to merge my passions for problem solving and teamwork, allowing me to contribute to the development of technologies and solutions that have a positive impact on the world around us.”About ACGFor over sixty years, ACG has been innovating the production solutions for pharmaceutical and nutraceutical companies, that help make people better. As the world’s most integrated provider of oral dosage products and services, we produce capsules, barrier packaging materials, manufacturing machinery, and visual inspection and traceability solutions. All fully compliant with international standards.Today, ACG fosters long-term collaborative partnerships with customers in 138 countries across six continents. Together, we share a common purpose: to solve the world’s greatest health challenges and make it better for everybody we serve. For more information, please contact the ACG media relations team:madhurima.chakraborty@acg-world.com

Read more

ACHEMA 2024: ACG Engineering on a mission to collectively ‘Make it Better’ World’s largest integrated supplier to the solid dosage manufacturing industry to display wide range of engineering and capsules products

At ACHEMA 2024 ACG Engineering, which provides end-to-end pharmaceutical engineering solutions,will be displaying its broadest range of products to date – underlining its commitment to ‘Making it Better’ for the industry and patients alike.The all-encompassing machines displayed will include the QUEST FB I, which is a highly versatile 'plug and play' fluid-bed unit for lab-scale feasibility studies. Also on show will be the ZRO 90T - a high-yield capsule filler. As will be the ACCURA 100FF - ACG's precision capsule checkweigher, suited for medium to large production batches with a capacity of 100,000 capsules per hour. Also on display will be the PROTAB 300 – a single rotary tablet press, which is suitable for R&D, small and medium-batch production, making scalability far easier, and the SECURECOAT TC III tablet coater, designed with operator safety and for use with highly potent active pharmaceutical ingredients (HPAPIs).Borja Guerra, vice president of international sales at ACG Engineering, said: “At ACG, we deliver efficient cutting-edge technology and a highly consistent ROI ratio for our global customer base, because we actively listen to them and their needs and take a collective approach towards ‘Making it Better’.“By aligning our shared strength and cross-divisional synergies with our Capsule and Films and Foils business units we are able to offer a whole world of different and highly targeted products and services – supporting large pharmaceutical companies and generic manufacturers with equal focus.”“We are really looking forward to ACHEMA 20024 and meeting with the industry to share knowledge and insights and to hopefully forge some new and exciting partnerships, continuing the expansion of ACG’s global footprint.”ACG will be exhibiting on stand A71 in Hall 3.1, between 10-14 June in Frankfurt.-Ends-About ACG For over 60 plus years, ACG has been innovating the production solutions for pharmaceutical and nutraceutical companies, that help make people better.As the world’s most integrated provider of oral dosage products and services, we produce capsules, barrier packaging materials, manufacturing machinery, and visual inspection and traceability solutions. All fully compliant with international standards.Today, ACG fosters long-term collaborative partnerships with customers in 138 countries across six continents.Together, we share a common purpose: to solve the world’s greatest health challenges and make it better for everybody we serve. For more information, please contact the ACG media relations team:madhurima.chakraborty@acg-world.com

Read more

Vantage Nutrition to champion ‘better delivery’ at Vitafoods Europe 2024

At this year’s Vitafoods Europe, Vantage Nutrition (an ACG group company), will be showcasing and championing the term ‘better delivery’. With a real focus on innovation, the team will be debuting the outstanding beadlet technology, a complete product offering ultimate ingredient performance.Other ACG Capsules products on show will include ACGcaps™ H+, the world's first independently certified* ‘Clean Label' eco-friendly capsule, which is made using thermogelation technology (water and cellulose only). Alongside will be the ACGcaps™ TSafe opaque and TiO2-free clean capsules, with the enhanced version offering flexibility with pigmentation options.Aaron Quinn, head of business development at Vantage Nutrition – Europe, commented: “We know that the world’s healthiest products demand the world’s cleanest capsules performance through more advanced technologies. Through our innovations, we are committed to supporting nutraceutical brands when it comes to time consuming and costly R&D.“With the development of beadlet technology we are able to offer ultimate ingredient performance and enhanced delivery. Beadlets release ingredients over time, boost absorption and improve bioavailability. And by working with one supplier, manufacturers can ensure they have full control over all processes, with the 360 service – ensuring better results and enhanced uptake.”ACG is the world’s largest integrated supplier of pharmaceutical and nutraceutical solid dosage products and services. Along with the commitment to delivering integrated solutions and cutting-edge technology, Vantage Nutrition aims to provide the most comprehensive and advanced multiphase solutions to customers globally. The team’s focus in on turning product ideas into reality fast – helping companies enable, enhance, and differentiate nutra brands - from a full-service partnership to specific value additions.ACG will be exhibiting on stand H37, between 14-16 May in Geneva.* Certifications are applicable to certain colours and/or variants.About ACG For over 60 plus years, ACG has been innovating the production solutions for pharmaceutical and nutraceutical companies, that help make people better.As the world’s most integrated provider of oral dosage products and services, we produce capsules, barrier packaging materials, manufacturing machinery, and visual inspection and traceability solutions. All fully compliant with international standards.Today, ACG fosters long-term collaborative partnerships with customers in 138 countries across six continents.Together, we share a common purpose: to solve the world’s greatest health challenges and make it better for everybody we serve. For more information, please contact the ACG media relations team:madhurima.chakraborty@acg-world.com

Read more

ACG Becomes the World’s First Capsule Manufacturing Factory to Join the Global Lighthouse Network Community 2023-24

ACG Capsules Pithampur, India is ACG’s 1st lighthouse to join the community Karan Singh, Managing Director and Balajikasiram Sundararajan, Chief Digital Officer attend the Global Light House Network ceremony in Davos to collect the award. ACG, the world's largest integrated supplier and service provider to pharmaceutical industry celebrated the inclusion of its capsule manufacturing facility in Pithampur, India, into the esteemed Global Lighthouse Network (GLN) by the World Economic Forum at the 54th Annual Davos Summit. The World Economic Forum’s Global Lighthouse Network has acknowledged the exemplary integration of Fourth Industrial Revolution (4IR) technologies, including artificial intelligence and big data analytics, by select factories globally. These facilities have been distinguished for their commitment to enhancing efficiency, fostering sustainable development, and simultaneously advancing their workforce’s skills and safeguarding the environment.Upon receiving the award, Mr. Karan Singh, Managing Director, said: “I am delighted to receive this recognition on behalf of my team. For me the most unforgettable part of our journey wasn't any technology or efficiency milestone, but the incredible team that made it all possible. Just ordinary people, united towards one goal, bringing about innovative collaborations to push boundaries of what is possible.” He added: “One of the stand-out features of our application was the Gen-AI integration. Something that was done in the less than two weeks. In between all the debate on what Gen-AI can do to humans it is a beautiful reminder that ‘technology is brilliant, but humans drive the change’. Let's remember that!”ACG operates across 138 countries in six continents and has positioned itself as a leader in the pharmaceutical sector by focusing on high-quality capsule production, increasing responsiveness, improving production yields, and boosting workforce efficiency. The company produces billions of capsules annually and has implemented over 25 innovative applications of 4IR technologies, including the industrial internet of things (IIoT), machine learning (ML), deep learning (DL), digital twins, extended reality, and generative AI.Selwyn Noronha, CEO, ACG Capsules, added: “We are extremely proud of our first factory lighthouse. From its inception the facility has pioneered in its field, but this latest honour recognises the excellence in adopting AI at speed and scale.“Our continued future-focused approach sets new benchmarks in quality and innovation, with the aim of ensuring maximum benefit for customers, regulators and the entire pharmaceutical ecosystem.”About Global Lighthouse Network Global Lighthouse Network is a collaborative platform bringing together forward-thinking manufacturers leading the charge in adopting Fourth Industrial Revolution technologies. Leveraging innovations like artificial intelligence, 3D-printing, and big data analytics, Lighthouses drive efficiency, competitiveness, and transformative business models at scale, fostering economic growth while championing workforce augmentation, environmental protection and providing a collaborative learning journey for all-sized manufacturers globally. The Global Lighthouse Network is a World Economic Forum initiative co-founded with McKinsey & Company and counselled by an Advisory Board of industry leaders, including Contemporary Amperex Technology (CATL), Foxconn Industrial Internet, Henkel, Johnson & Johnson, Koç Holdings, Schneider Electric, and Siemens. Factories and value chains that join the network are designated by an independent panel of experts.About ACG For over 60 plus years, ACG has been innovating the production solutions for pharmaceutical and nutraceutical companies, that help make people better. As the world’s most integrated provider of oral dosage products and services, we produce capsules, barrier packaging materials, manufacturing machinery, and visual inspection and traceability solutions. All fully compliant with international standards. Today, ACG fosters long-term collaborative partnerships with customers in 138 countries across six continents. Together, we share a common purpose: to solve the world’s greatest health challenges and make it better for everybody we serve.For more information, please contact the ACG media relations team:madhurima.chakraborty@acg-world.com

Read more

ACG awarded ‘Great Place To Work’ certification for a fourth consecutive year

ACG, the world’s largest integrated supplier and service provider to the pharmaceutical industry, is delighted to announce that for the fourth consecutive year, it has achieved the ‘Great Place To Work’ certification. This certification recognises employers who create an outstanding employee experience.Within ACG, five business units (Capsules, Corporate, Scitech – Research and Development Centre, Machinery, and Inspection), have been certified as a ‘Great Place to Work’. The comprehensive study, spanning five locations in India, encompassed approximately 3000 associates across management and plant categories. The process entailed a thorough survey based on key levers that define an organization's culture.Nikita Panchal, Group Head Talent, OD and DEI at ACG, said: “Winning this award for the fourth consecutive year fills me with pride and gratitude, recognizing the collective effort of our associates. It serves as a reminder of our commitment to excellence and the fact that institution-building is at the centre of all our actions as an organization.“ACG fosters collaboration by nurturing teamwork and effective communication. We care for our associates and the business community through support initiatives, and we remain progressive by supporting change and innovation. Our associates are encouraged to embrace our values, seize opportunities for growth and contribute their unique talents to shape a bright future together.”Sunil Jha, Group CHRO of ACG Group, added: “ACG thrives on collaboration through cross-functional teamwork, and – at all times – we prioritize the wellbeing of our associates.“Winning this award is incredibly gratifying and I am appreciative that all our associates have worked together to make this happen.”-Ends-About ACGFor over sixty years, ACG has been innovating the production solutions for pharmaceutical and nutraceutical companies, that help make people better. As the world’s most integrated provider of oral dosage products and services, we produce capsules, barrier packaging materials, manufacturing machinery, and visual inspection and traceability solutions. All fully compliant with international standards.Today, ACG fosters long-term collaborative partnerships with customers in 138 countries across six continents. Together, we share a common purpose: to solve the world’s greatest health challenges and make it better for everybody we serve. For more information, please contact the ACG media relations team:madhurima.chakraborty@acg-world.com

Read more

Interphex 2024: ‘ACG focuses on lowering manufacturer’s TCO’

At this year’s Interphex, ACG Engineering, part of ACG - the world's only integrated pharmaceutical solutions and manufacturing company - will be focusing on its cost-effective approach to taking generics to market.ACG’s methodology is based on speed-to-market, production efficiency and reducing manufacturing costs.Borja Guerra, vice-president of international sales at ACG, said: “As a highly experienced global supplier of process and packaging machinery of all oral solid dosage requirements, we are attuned to local market requirements. We aim to provide a low TCO (total cost of ownership) for premium pharmaceutical equipment.“With over six decades of experience partnering in the oral solid dosage space, we have taken over 8000 generics to market, working with more than 1000 pharmaceutical manufacturers to achieve this.”ACG will be showcasing its ACCURA 100 FF. The capsule checkweigher is designed specifically for precise, automatic, and continuous weighing of each capsule – whether empty, filled or partially filled, with anything from powder to pellets, and which is format free.ACG is the world’s largest integrated supplier of pharmaceutical and nutraceutical solid dosage products and services. The company will be exhibiting on stand 3515 between 16-18 April in New York.About ACG For over 60 plus years, ACG has been innovating the production solutions for pharmaceutical and nutraceutical companies, that help make people better.As the world’s most integrated provider of oral dosage products and services, we produce capsules, barrier packaging materials, manufacturing machinery, and visual inspection and traceability solutions. All fully compliant with international standards.Today, ACG fosters long-term collaborative partnerships with customers in 138 countries across six continents.Together, we share a common purpose: to solve the world’s greatest health challenges and make it better for everybody we serve. For more information, please contact the ACG media relations team:madhurima.chakraborty@acg-world.com

Read more

ACG Inspection launches new cloud-based offering to address upcoming VRS requirements under DSCSA regulations

In light of the impending Drug Supply Chain Security Act (DSCSA) regulations, ACG Inspection, a leading track and trace solutions provider for the pharmaceutical industry, has launched its new cloud-based Verification Router Service (VRS).The new system, which forms part of the ACG’s Inspections Life Sciences Cloud Service and Compliance Gateway, enables the automatic verification of saleable returns through product identifiers by routing requests and responses between stakeholders. Serialized products are assigned a unique identifier that can be used to track the product throughout its entire journey, enabling wholesalers to verify the authenticity of the products before they are resold.Shine Vijayan, CTO at ACG, commented: “The regulations, which have now been delayed by 12 months (coming into force in November 2024), will require all trading partners in the pharmaceutical supply chain to verify the identifier of any serialized drug product before redistributing it.“ACG’s existing VeriShield solutions tackles the implementation and interoperability challenges faced at Level 1, through to Level 3. With DSCSA’s regulation in place, ACG’s VRS covers level 4 - helping pharmaceutical manufacturers, distributors and retailers easily track and verify the saleable returns and secure their supply chain from counterfeit and substandard products.“ACG works closely with its customers, helping to address their pain points - one of which being concerns around data security. Our VRS employs robust security measures to safeguard serialized product information, guaranteeing the confidentiality and integrity of sensitive data throughout the verification process.”The system also guarantees real-time verification, to enhance operational efficiency and prevent supply chain delays. Additionally, it provides scalability assurance to accommodate an expanding volume of serialized data, to ensure continued robustness and reliability. And it incorporates exception handling, empowering stakeholders to address issues promptly to help maintain supply chain integrity.Shine Vijayan: “We are trusted experts and through our Life Sciences Cloud Service and Compliance Gateway, we can support counterfeit prevention, improving recall efficiency and data security. At all times, ensuring our clients are fully compliant with international standards and ready to meet the requirements as laid out in the impending DSCSA regulations.” -Ends- About ACGFor over sixty years, ACG has been innovating the production solutions for pharmaceutical and nutraceutical companies, that help make people better. As the world’s most integrated provider of oral dosage products and services, we produce capsules, barrier packaging materials, manufacturing machinery, and visual inspection and traceability solutions. All fully compliant with international standards.Today, ACG fosters long-term collaborative partnerships with customers in 138 countries across six continents. Together, we share a common purpose: to solve the world’s greatest health challenges and make it better for everybody we serve. For more information, please contact the ACG media relations team:madhurima.chakraborty@acg-world.com

Read more

ACG Engineering launches the Smart Coater X.ONE Series Company’s fastest tablet coater ensures optimised production processes

ACG Engineering, a division of ACG, a leading supplier of integrated manufacturing solutions to the global pharmaceutical and nutraceutical industries, is delighted to launch its new Smart Coater X.ONE series, the company’s fastest tablet coater to date.The Smart Coater X.ONE has been designed to make tablet coating extremely fast, with an extra emphasis on process speed, efficiency and operator ease. Its advanced baffle design ensures the quickest process times for batches from 10-100%.Features of the new coater include a unique airflow pattern for optimized drying, a fully-perforated coating drum, closed dust-free charging, integrated discharge baffles, temperature sensor, a high-performing spray-arm and a 2.0 spray nozzle which has been developed with an anti-bearding cap. It also incorporates ACG’s exclusive X•ONE command and control system, designed to facilitate compliance with cGMP standards. Richard Stedman, CEO at ACG Engineering, said: “Our Smart Coater machines are already renowned for their innovative features and operator friendly designs. Now, after a lengthy period of development, we are excited to announce the launch of the X.ONE series.“Our quality-commitment philosophy means that the new machine has been crafted to achieve maximimum efficiency and flexibility for superior tablet coating, across every process – from charging to coating, discharging to cleaning. Each and every cycle is now swifter, more streamlined and profitable.“The fast tablet coater to date is already garnering real interest, and we look forward to continuing to showcase it capabilities at the upcoming CPhI event in Barcelona at the end of the month.” (XXX – may want to adapt this sentence, to reflect true accuracy)-Ends-About ACGFor over 60 years, ACG has been innovating the production solutions for pharmaceutical and nutraceutical companies, that help make people better.As the world’s most integrated provider of oral dosage products and services, we produce capsules, barrier packaging materials, manufacturing machinery, and visual inspection and traceability solutions. All fully compliant with international standards.Today, ACG fosters long-term collaborative partnerships with customers in 138 countries across six continents. Together, we share a common purpose: to solve the world’s greatest health challenges and make it better for everybody we serve.For more information, please contact the ACG media relations team:madhurima.chakraborty@acg-world.com

Read more

ACG acquires Technical Aluminium Foil Company

Further underpinning business growth across the Middle Eastern and African marketsACG announces full shareholding ownership of Technical Aluminium Foil Company (TAFC). This strategic move further solidifies ACG's growth trajectory across the Middle Eastern and African markets.As the world's only integrated pharma manufacturing solutions company, ACG offers a diverse range of products including capsules, films, foils, engineering equipment and inspection systems. The addition of TAFC, a prominent aluminium foil packaging company based in the UAE, strengthens ACG's position as a leading provider of comprehensive packaging solutions.TAFC boasts over a decade of experience serving the pharmaceutical and food industries with its extensive range of aluminium and specialty packaging foils renowned for their exceptional high barrier properties. The company's expertise in lacquering, lamination, printing and slitting further enhances ACG’s capabilities in meeting the diverse packaging needs of its clients.This acquisition represents ACG Group's inaugural venture in the Middle East, following recent successful acquisitions of ComboCap and AquaCap in the Americas. TAFC seamlessly aligns with ACG Films and Foils' existing business operations, enabling both entities to harness their collective strengths and expertise for accelerated growth.Shivshankar S.R., CEO at ACG Films & Foils, said: “We are excited to be making our first acquisition in the UAE. This strategic collaboration will further support our work in bringing innovative and high-quality packaging products to market, while reducing lead times and improving service levels.“By joining forces, the companies will be able to leverage their combined strengths and expertise to propel the business forward in the Middle Eastern and African markets.”-Ends-About ACGIn accordance with its commitment to making the world healthier, ACG has been delivering exceptional solutions to the global pharmaceutical and nutraceutical industry for sixty years, across six continents and in a hundred countries.Collaboration is at the core of ACG’s ethos. ACG is the world’s only integrated pharma manufacturing solutions company, with products ranging from capsules to films & foils, to engineering equipment and inspection systems – all that meet international regulatory requirements. For ACG, it’s always about finding innovative solutions to the world’s greatest health challenges, together.For more information, please contact the ACG media relations team:madhurima.chakraborty@acg-world.com

Read more

Vantage Nutrition LLC acquires ComboCap Inc

This acquisition positions Vantage Nutrition as the only company in the world supplying Sidebysideä health products to nutritional and pharmaceutical markets, for enhanced combinations.Vantage Nutrition, an ACG group company announces full shareholding ownership of ComboCap Inc (USA) and BioCap (South Africa).ComboCap is renowned for the invention and commercialization of its Sidebyside technology, the world’s first three-piece capsule health product that contains an internal divider, enabling wet and dry ingredients to be brought to market side by side, separated-but-together. Backed by 80 international patent awards ComboCap has been supplying nutritional brand customers with unique finished product solutions out of its cutting-edge cGMP plant in NJ, USA. This acquisition marks a significant milestone for Vantage Nutrition and ACG, as it further expands its technology and customer solutions footprint in North America and around the world.ACG is the world’s largest integrated supplier of pharmaceutical and nutraceutical solid dosage products and services. Vantage Nutrition, an ACG group company, already has an excellent reputation as an innovator of liquid filled capsule solutions. ComboCap marks Vantage Nutrition’s second US investment in less than a year, and first in S.A, after Philadelphia-based ‘AquaCap’ was acquired from Nestlé S.A. With this expansion of manufacturing capabilities and patented technology, along with the commitment to delivering integrated solutions and cutting-edge technology, Vantage Nutrition aims to provide the most comprehensive and advanced multiphase solutions to customers globally.Karan Singh, Managing Director at ACG, said, "As one of world’s largest producers of empty hard-shell capsules, at ACG we have often thought, what next? Strengthening our portfolio of most comprehensive vegetarian and gelatin capsules, in every imaginable size, I am thrilled to announce the acquisition of ComboCap Inc and BioCap. We now will hold the patented design and specialized equipment used inproducing the world’s first 2-in-1 capsule product with a movable membrane, becoming the sole proprietor of this technology globally.With our partners, we will usher a new era in new combinations of dietary supplements, and even non-prescription or over-the counter (OTC) remedies as well as prescription (Rx) medicines to be delivered in a single dose. This technological breakthrough is a solution to current formulation challenges with many combination therapies, including incompatible ingredients or molecules. Capsules are arguably the safest and most reliable way to deliver medicine and we at ACG strive to make it better.”Tobie Louw, a Founder and CEO of ComboCap Inc, said: “Vantage Nutrition is the perfect partner for our business, and we are very excited to be part of the ACG family. We share a passion for innovation and the commitment to bring nutraceutical and pharmaceutical customers the best possible solutions and services. By joining forces and leveraging our collective capabilities we’ll no doubt bring Sidebysideä to nutraceutical and pharmaceutical markets the world over.”-Ends-About Vantage NutritionVantage Nutrition, part of the ACG Group, is one of the world’s largest and most respected manufacturer of hard-shell liquid-fill capsule solutions. As a strategic consultancy and manufacturing partner in the nutraceutical space, Vantage Nutrition helps clients bring high-quality and innovative products to market, fast. About ACGIn accordance with its commitment to making the world healthier, ACG has been delivering exceptional solutions to the global pharmaceutical and nutraceutical industry for sixty years, across six continents and in a hundred countries.Collaboration is at the core of ACG’s ethos. ACG is the world’s only integrated pharma manufacturing solutions company, with products ranging from capsules to films & foils, to engineering equipment and inspection systems – all that meet international regulatory requirements. For ACG, it’s always about finding innovative solutions to the world’s greatest health challenges, together.For more information, please contact the ACG media relations team:madhurima.chakraborty@acg-world.com

Read more

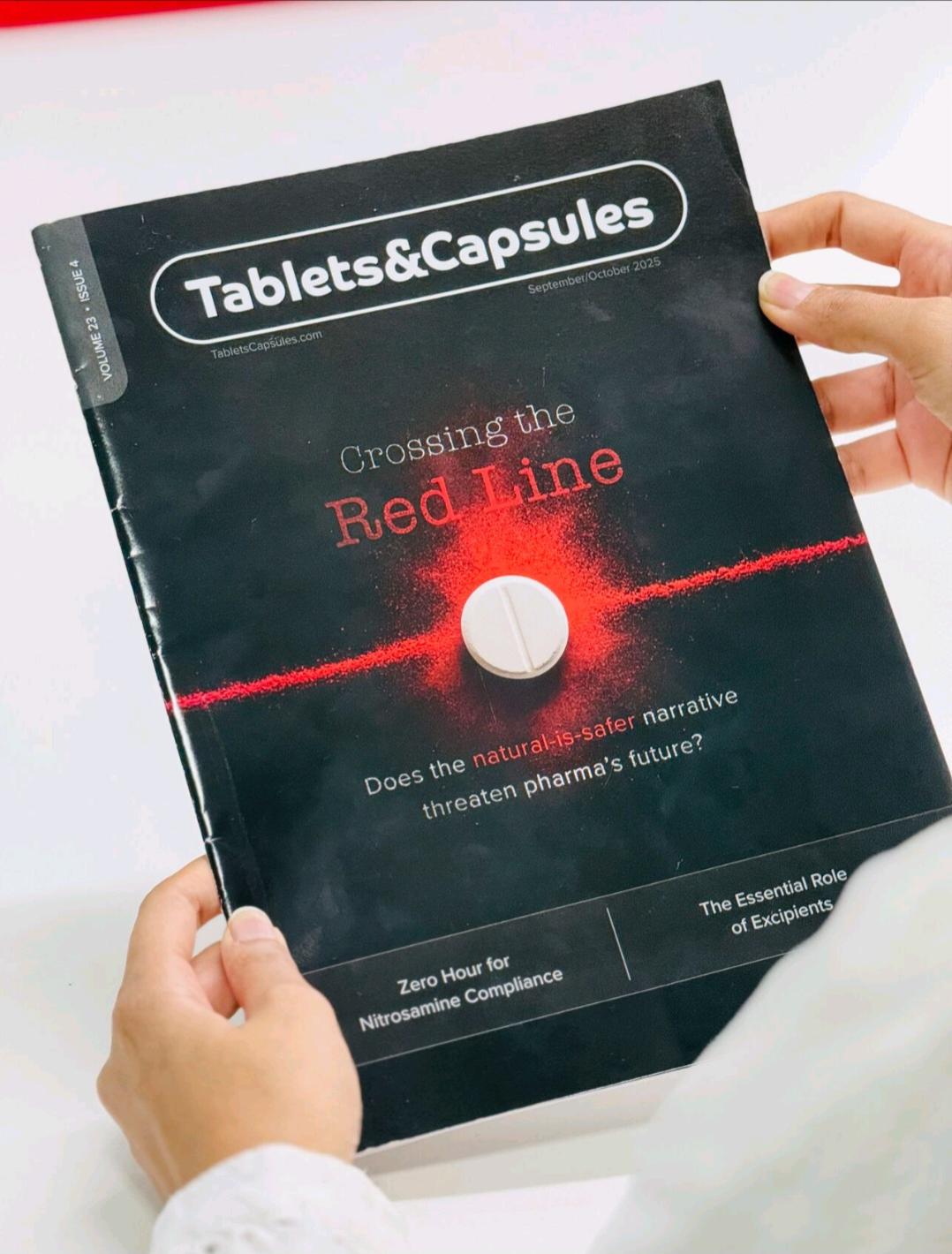

ACG Engineering – SECUREFILL 40T

Tablets & CapsulesCapsule Filling Equipment & Supplies (February 2023)ACG Engineering – SECUREFILL 40TThe Securefill series is ACG’s high-level containment capsule-filling machine range. Designed for filling capsules with highly potent and/or toxic drugs, the machines comply with occupational exposure band (OEB) up to level 4.Built with operator safety in mind, these machines are equipped for filling capsules with oncological, biopharmaceutical, antiviral formulations, and other such highly potent active pharmaceutical ingredients (HPAPIs).Features:• SS316L monoblock structure containing HEPA filters, a rapid transfer port (RTP), glove ports, and accurate dosing mechanisms maintained in a negative pressure environment.• Provision for contained charging and discharging.• Wet-in-place system to ensure wetting of all suspended particles in the pharma zone.• Can be integrated with check-weighers, metal detectors and de-dusters under containment conditions.Benefits:• Ensures complete containment, thereby avoiding operator contact within OEL range 1-10µg/m3.• Integrated containment philosophy for upstream and downstream processes.• Enables easy cleaning.• Supports the production of life-saving drugs that contain HPAPIs.Technical specifications: SECUREFILL 40T Capsule size 00 - 5 Maximum speed 40,000 capsules/hour OEL 1-10µg/m3About ACGIn accordance with its commitment to making the world healthier, ACG has been delivering exceptional solutions to the global pharmaceutical and nutraceutical industry for sixty years, across six continents and in a hundred countries.Collaboration is at the core of ACG’s ethos. ACG is the world’s only integrated pharma manufacturing solutions company, with products ranging from capsules to films & foils, to engineering equipment and inspection systems – all that meet international regulatory requirements. For ACG, it’s always about finding innovative solutions to the world’s greatest health challenges, together.For more information, please contact the ACG media relations team:madhurima.chakraborty@acg-world.com

Read more

Vantage Nutrition LLC acquires Aquacaps from Nestlé Health Science

Vantage Nutrition’s innovative nutraceutical offering expands into North America.. Vantage Nutrition, an ACG Group company, announced on 1st December 2022 that it has acquired Philadelphia-based ‘Aquacaps’ – an asset of Nestlé Health Science. Aquacaps is a leading contract manufacturer of liquid-filled capsules within the nutritional supplement industry in the United States. Its novel liquid delivery technology allows for the liquid filling of hard gelatin and vegetarian capsules. ACG is the world’s largest integrated supplier of pharmaceutical and nutraceutical products and services. Vantage Nutrition, an ACG group company, already has an excellent reputation as an innovator of two-piece liquid fill capsule solutions. The company’s mission is to be the most efficient partner in delivering innovative and high-quality nutraceutical products to customers globally. Karan Singh, Managing Director of ACG, said: “Although ACG has been established in North America for the last 20 years, this marks our first acquisition in the territory and is a key next step in our global expansion strategy. With this increase in our footprint and manufacturing capabilities, coupled with Vantage’s innovative technologies and 360-degree service offering, we aim to provide the most advanced combination liquid-fill solutions for customers across the region.” About VantageVantage Nutrition, part of the ACG Group, is one of the world’s largest and most respected manufacturer of hard-shell liquid-fill capsule solutions. As a strategic consultancy and manufacturing partner in the nutraceutical space, Vantage helps clients bring high-quality and innovative products to market, fast. About ACGIn accordance with its commitment to making the world healthier, ACG has been delivering exceptional solutions to the global pharmaceutical and nutraceutical industry for sixty years, across six continents and in a hundred countries.Collaboration is at the core of ACG’s ethos. ACG is the world’s only integrated pharma manufacturing solutions company, with products ranging from capsules to films & foils, to engineering equipment and inspection systems – all that meet international regulatory requirements. For ACG, it’s always about finding innovative solutions to the world’s greatest health challenges, together.For more information, please contact the ACG media relations team:madhurima.chakraborty@acg-world.com

Read more

ACG appoints Shankar Gupta as Chief Sales Officer Industry authority to re-join business in a newly created role

ACG, the world’s largest integrated pharmaceutical and nutraceutical manufacturing solutions provider, is delighted to announce that Shankar Gupta will be re-joining the business in the newly created role of Chief Sales Officer.In his new role, Shankar will be responsible for driving sales across all four ACG divisions (Films and Foils, Capsules, Inspection and Engineering) in order to continue building the company’s ‘One ACG’ agenda. Essentially, this will involve bringing further uniformity to ACG's customer outreach processes, creating more integrated solutions, and ultimately providing a consistent brand experience to ACG’s global customers, regardless of business division or location. He will also focus on scaling new initiatives.Shankar will report directly into the managing director, Karan Singh, who comments:"I am so pleased that Shankar Gupta has decided to rejoin the business during this exciting time. His understanding of ACG and its deliverables, and deep insight into our customers’ businesses will help us to align ourselves better to their changing needs. More importantly, he will champion and support better collaboration and partnership with customers.“Shankar will be pivotal in calibrating and aligning our business units to our goal of ‘Making it Better’, and our belief that everyone deserves access to good medicine."Shankar Gupta adds: “I am excited to use my experience in the pharmaceutical industry to augment ACG's growth by aligning the organisation to the changing dynamics of the global healthcare Industry.“It will certainly call for a huge collaboration of efforts both internally and with our customers, but will ultimately lead to a richer, deeper and more numerous partnerships.”-Ends-About ACGIn accordance with its commitment to making the world healthier, ACG has been delivering exceptional solutions to the global pharmaceutical and nutraceutical industry for sixty years, across six continents and in a hundred countries.Collaboration is at the core of ACG’s ethos. ACG is the world’s only integrated pharma manufacturing solutions company, with products ranging from capsules to films & foils, to engineering equipment and inspection systems – all that meet international regulatory requirements. For ACG, it’s always about finding innovative solutions to the world’s greatest health challenges, together.For more information, please contact the ACG media relations team:madhurima.chakraborty@acg-world.com

Read more

ACG appoints Udit K Singh as CEO of ACG Inspection

ACG, a leading supplier of fully integrated manufacturing solutions to the global pharmaceutical and nutraceutical industry, is pleased to announce the appointment of Mr. Udit K Singh as the new chief executive officer (CEO) of its Inspection Division.Mr. Singh will be supporting the company as it continues its growth and global expansion. He will be responsible for ensuring that every dose of medication that ACG Inspection’s pharmaceutical and nutraceutical partners provide is manufactured and delivered exactly as intended. That is down to the fact that ACG’s visual inspection systems track and monitor the manufacturing lines to guarantee flawless, safe products.Karan Singh, managing director, ACG said: “ACG is focused on building a diverse, world-class team by hiring top international talent. We are delighted to welcome Udit Singh to ACG Inspections. He has had an illustrious career and brings diverse and unique capabilities, including a robust understanding of the pharmaceutical sector.“The team looks forward to tapping into his deep experience to enrich our global work towards making the world safer and healthier. With his knowledge and expertise in this field, Udit Singh is sure to take ACG Inspection to newer heights.”Mr. Singh added, “I am pleased to join ACG and will work to ensure that our advanced serialisation, aggregation and anti-counterfeiting solutions track and protect medicines all the way through the supply chain, and into the hands of those who need them.“We are investing substantially to ensure our track and trace platform performs seamlessly and complies with regulatory requirements all over the world. I look forward to playing an integral role, and contributing towards the continued development, working with a world-class team.”About ACGIn accordance with its commitment to making the world healthier, ACG has been delivering exceptional solutions to the global pharmaceutical and nutraceutical industry for almost sixty years, across six continents and in a hundred countries.Collaboration is at the core of ACG’s ethos, and ACG is the world’s only integrated pharma manufacturing solutions company, with products ranging from capsules to films & foils, to engineering equipment and inspection systems – all that meet international regulatory requirements. For ACG, it’s always about finding innovative solutions to the world’s greatest health challenges, together.For more information, please contact the ACG media relations team:madhurima.chakraborty@acg-world.com

Read more

ACG Capsules launches campaign to promote problem-free pharmaceutical production

-One of the world’s largest producers of empty hard-shell capsules is on a mission to‘Love NOTHING’ when it comes to zero-problem productionACG, one of the world’s largest producers of empty hard-shell capsules, has launched its global pharmaceutical campaign: ‘ACG loves NOTHING’. The campaign is aimed at significantly improving pharmaceutical production through collaboration and industry-leading innovation. With a host of value-added services on offer, ACG has taken a pledge to strive for zero-problem pharmaceutical and nutraceutical manufacturing.Alex Robertson, CMO at ACG, said: “The messaging at the centre of this campaign is: ‘ACG loves NOTHING’ – we are putting every effort towards zero-problem production. That’s because when ‘nothing’ happens during pharmaceutical and nutraceutical production, everything runs reliably, and our customers can get the products they make to the people who need them. We will achieve this by providing the highest quality empty capsules and all the holistic advice and expertise required for seamless operations.”Founded 60 years ago, ACG was created on the simple principle of ‘Make it Better’. As the world’s largest integrated supplier of solid dosage pharmaceutical and nutraceutical products, and with the most comprehensive ranges of vegetarian and gelatin capsules globally, ACG has the scale and range to have a far-reaching impact on pharmaceutical production and human health.Selwyn Noronha, CEO ACG Capsules, added: “The pharmaceutical sector is regulated and highly competitive. Companies operating within it need a diverse range of quality capsules that help them stand out from the crowd, while also meeting demands for clean and natural products.“Beyond exceptional products, these companies need expertise and a lifetime of targeted support to ensure efficient manufacturing and guarantee regulatory compliance. With proficiency in all aspects of manufacturing from capsules to machines and protective barriers, for the last 60 years ACG has been the only company to offer this level of support, and it continues with this focus at the heart of operations.”So, at ACG, there really is something about NOTHING. The company is on a mission to drive towards problem free production and collaborating with its customers to collectively deliver on its mission of creating a healthier world.About ACGIn accordance with its commitment to making the world healthier, ACG has now been delivering exceptional solutions to the global pharmaceutical and nutraceutical industry for 60 years, across six continents and in 138 countries.‘Collaboration’ is at the core of ACG’s ethos, and ACG is the world’s only integrated pharma manufacturing solutions company, with products ranging from capsules to films & foils, to engineering equipment, and inspection systems – all that meet international regulatory requirements.For ACG, it’s always about finding innovative solutions to the world’s greatest health challenges, together.For more information, please contact the ACG media relations team:madhurima.chakraborty@acg-world.com

Read more

Tackling regulatory challenges through collaboration

Tackling regulatory challenges through collaboration

Shincy Jacob, sr. manager global product management, Samata Karwakar, GM quality & regulatory affairs, Patricia Shetty, VP quality & regulatory affairs, Dr.Subhashis Chakraborty, head global product management at ACG World discuss tackling regulatory challenges through collaboration.Stories that link cancer risks to pharmaceutical and nutraceutical ingredients like titanium dioxide (TiO2), Red Dye No. 3 and nitrosamines hit news sites on what seem like a regular basis, but the reality is never as simple as the headlines may suggest. Regulatory bodies like the US Food & Drug Administration (FDA), European Medicines Agency (EMA), and the European Commission (EC) are right to be cautious when any adverse health effects are linked to excipients found in medicines and healthcare products. However, imposing blanket bans without a full picture of the impact and viability of such restrictions can interrupt vital research and lead to shortages of medicines as well as cause reputational damage and wasted time and budget.Tackling the complex challenges of identifying and interpreting impurities, contaminants, and anomalies that arise during pharmaceutical testing requires a more measured and holistic approach. Regulatory bodies need to communicate, share data, and collaborate with formulators, excipient and component suppliers and pharmaceutical manufacturers throughout the process to ensure patient safety and efficacy. This transparency will help avert any unnecessary panic and avoid unintended consequences that can arise from isolated actions. Beyond the headlinesFollowing the EC’s ban of TiO2 as a food additive in 2022, the pharmaceutical industry began evaluating the safety of the whitening agent in medicinal products. Companies like ACG invested in our own research into the feasibility of using TiO2-free alternatives. After careful evaluation, we identified the complexities and technical limitations of eliminating the agent, communicating to our customers and the industry that an exact replacement with the same properties would not be possible with current material science.By sharing findings with industry organisations like the IQ Consortium, we have been able to help suppliers across the pharmaceutical supply chain to make informed and strategic decisions about their use of the additive. This evidence-based approach allowed them to avoid operating in the dark and respond blindly to the regulatory changes. Understanding Nitrosamine risksIn pharmaceuticals, safety concerns don’t always come from a single ingredient — sometimes they arise when materials interact. Nitrosamines are a good example. Nitrosamines are chemical compounds that can form when substances containing amines react with nitrites under conditions such as heat, moisture or acidity. Because several nitrosamines are classified as probable human carcinogens, even trace levels in medicines are a major safety concern. Nitrosamines were first detected as N-nitrosodimethylamine (NDMA) in Valsartan (2018), followed by N-nitrosodiethylamine (NDEA) and N-nitrosomethyl-4-aminobutyric acid (NMBA) in other sartans like Losartan and Irbesartan (2019), and later in Ranitidine (2020), extending the issue beyond blood-pressure drugs and prompting global recalls.In response to emerging risks, regulatory authorities have established stringent limits on allowable nitrosamine levels in drug products. While the initial focus was largely on active pharmaceutical ingredients (APIs), increasing awareness has expanded attention to excipients as potential contributors. A shared responsibilityDespite being typically regarded as low-risk contributors to nitrosamine formation, under certain conditions, excipients can still play a role. For example, excipients that contain amines or nitrites may pose a higher risk when combined with specific formulation matrices and storage environments. Excipient suppliers take these risks seriously and are playing a pivotal role in industry-wide risk mitigation by implementing nitrite controls and periodic nitrite testing, collaborating with drug manufacturers to help minimise nitrosamine concentration in end products. Assessing the riskFor excipient manufacturers, managing nitrosamine risk begins with a thorough understanding of the raw materials used to make their products. It is critical to determine whether any incoming materials contain amine groups, as these can act as precursors for nitrosamine formation once the excipient is combined with an API. Tools such as the IPEC questionnaire have been valuable in early assessments of these excipients.Excipient manufacturers must also consider how their products might influence Nitrosamine Drug Substance Related Impurities (NDSRIs), which are nitrosamines structurally related to the API or its fragments. Even though NDSRIs are specific to the API, interactions with excipients—especially under certain manufacturing or storage conditions—can affect their formation.Although nitrosamines constitute a recognised safety concern, their relevance is not universal across all pharmaceutical products, due to well-established scientific and mechanistic considerations. It is therefore critical that scientists engage with excipient suppliers in a deliberate and evidence-driven manner, avoiding undue pressures that could inadvertently increase project complexity, delay product development timelines, and elevate overall costs.A closer look at capsulesEmpty hard capsules (EHCs) are an example of critical excipients used widely in solid oral drug products, serving as protective shells for carrying the active pharmaceutical ingredients (APIs). Due to their direct contact with drug formulations, strict control over their raw materials and manufacturing processes is essential to minimise any potential nitrosamine-related risks. Gelatine and Hydroxypropyl Methylcellulose (HPMC) capsules each present unique considerations due to their distinct compositions and properties.Derived from collagen, gelatine is a natural protein composed of amino acids. Because of its biological origin, gelatine can inherently contain trace amounts of nitrites, which may arise from raw material sources or processing conditions. Elevated nitrite levels in gelatine raise concerns about nitrosamine formation and therefore require stringent sourcing protocols, rigorous nitrite monitoring, and tightly controlled manufacturing processes. HPMC capsules, made from a cellulose derivative, generally pose a lower risk of nitrosamine formation due to their chemically inert chemical structure. HPMC itself is free from amino groups that could react with nitrosating agents, reducing the likelihood of nitrosamine formation. For example, ACG’s “H Plus” capsules—which contain only HPMC and water, without additional gelling agents—offer an even lower risk profile, especially in clear, transparent formulations where minimal additives are used. Safety through monitoring, mitigation, and collaborationFor both gelatine and HPMC capsules, continuous monitoring of raw material quality, combined with targeted mitigation strategies, is vital to uphold product safety and meet evolving regulatory requirements. Collaboration between raw material suppliers, capsule manufacturers, pharmaceutical companies, and regulatory authorities helps to drive innovation in quality control and analytical testing, ensuring that capsule excipients remain reliable components in modern drug delivery systems.A structured approach with proactive supplier engagement is essential to strengthen safeguards and to help ensure the safety of capsule-based drug products from unnecessary risks. This should encompass: raw material quality control, manufacturing process optimisation, constant analytical monitoring, robust packaging, appropriate storage controls, detailed risk assessment, meticulous documentation and ongoing collaboration.Early and continuous collaboration across the entire supply chain helps identify high-risk APIs, manage nitrite levels and maintain effective controls throughout the product lifecycle –ensuring the integrity of medicines, healthcare products and the wider pharmaceutical supply chain, while confidently addressing emerging concerns. .common-article-page .custom-container ul li::marker { color: #000; } .common-article-page .custom-container ul li{ color:#000; }

Read more

ACG Packaging Materials Launches SuperPodTM Setting a new benchmark for cold-fo…

ACG Packaging Materials Launches SuperPod™

ACG Packaging Materials, which manufactures the world’s widest range of film and foil blister and lidding products, has launched its breakthrough cold-form blister technology, SuperPod™.Delivering meaningful advances in sustainability and efficiency, SuperPod™ enables blister cavities to become dramatically smaller – by up to 39 per cent in some cases while maintaining full barrier performance and seamless machine runnability. This cold-form innovation results in a significantly reduced packaging footprint, lower material and resource usage per dosage across the lifecycle, and consequently, reduced costs and carbon emissions.Traditional cold-form aluminium blister cavities are large because they cannot be drawn deeply without the risk of aluminium rupture. Larger cavities increase the size of primary, secondary, and tertiary packaging, leading to higher material consumption, warehouse space requirements, and logistics costs.The core innovation behind SuperPod™ lies in a superior multi-layer laminate engineered for exceptional cold-drawing capability, enabling deep-draw cavity formation while retaining the full protective properties of cold-form aluminium. A well-designed format also increases the number of blisters per shot—by up to three times in some cases—freeing up production capacity and reducing manufacturing costs.SuperPod™ ensures smooth and reliable performance on existing high-speed packaging lines. In addition, it is available with both PVC-based and halogen-free sealing layers. Together, these benefits make SuperPod™ a compelling solution for manufacturers seeking to improve both operational efficiency and environmental impact.Dr Akbar Ali, General Manager and Head of Development and Technology, ACG Packaging Materials, commented “We’re excited to debut SuperPod™ at Pharmapack 2026. The technology effectively makes cold-form blisters lighter by reducing material usage per dosage. We see significant opportunities, particularly for high-count formats such as 20-count vitamins and B-complex capsules, where traditional cold-form blisters become impractically large. It also performs exceptionally well for moisture-sensitive and oncology products, where reduced headspace and narrower cavity spacing help minimise gas and moisture exposure, offering enhanced protection. SuperPod™ has already undergone testing with major pharmaceutical manufacturers on high-speed blister lines, demonstrating performance comparable to standard cold-form materials, but with far greater forming capability.”Jochen Scheil, Vice President, Global Sales and Business Development, added “The launch of SuperPod™ encourages the industry to rethink decades-old design conventions and embrace smaller, smarter, and more sustainable blister formats. Digital tools such as QR codes and electronic leaflets further support this transition by reducing reliance on large blister surface areas for printed information.”SuperPodTM will be launched at Pharmapack Paris for the European market on stand 4H12 (Hall 4). ACG will also be displaying from its range of sustainable materials and barrier protection products including:RecycloPodTM – recycle ready mono material,DryPodTM – desiccant based active cold form laminates,AlumLid EcoTM – sustainable lidding foil suitable for online printing and high-speed machine,Sustainable cold form – PVC, and halogen free symmetrical cold form materialCR SF lidding foil – creating an industry benchmark,UltrasafeTM – thermoforming materials with high level barrier protection, andSupposeTM – wide range of thermoform and cold form suppository material for all types of forming machines. .common-article-page .custom-container ul li::marker { color: #000; } .common-article-page .custom-container ul li{ color:#000; }

Read more

Smarter and Sustainable Pharma Manufacturing with ACG Engineering

Smarter and Sustainable Pharma Manufacturing with ACG Engineering