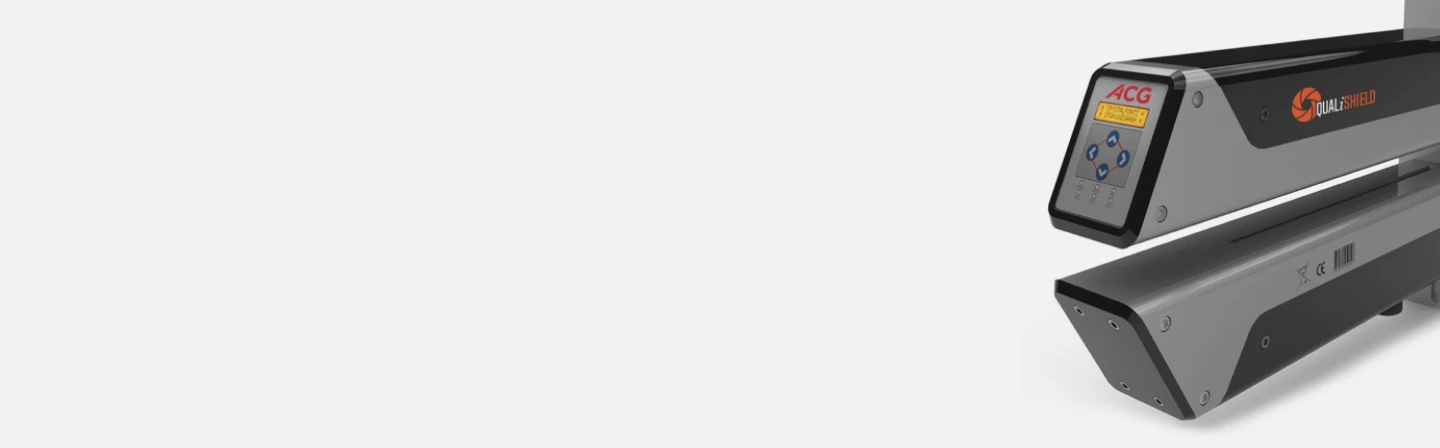

About the QualiShield® PH10

Our state-of-the-art scanning system is a non-destructive pinhole detection solution designed specifically to detect surface imperfections on aluminium foils. It detects pinholes, micro-leaks or pores anywhere in the inspection window, inspects base aluminium foils after forming, and checks lidding foils before sealing. And you can tailor it to the full range of format sizes available on blister-packaging machines.

Applications

Detection of pinholes, micro-leaks, and integrity failures in forming and lidding foils without damaging the material

| Features | Benefits | |

|---|---|---|

Detects pinholes with diameters as small as 25 μm

Detection sensitivity is adjustable to suit user requirements | 100% real-time inspection of pores, fissures and pinholes on lidding and base foils | |

Compatible with aluminium foils of different widths and lengths | Assured performance, irrespective of aluminium foil types and sizes | |

GMP-compliant | A regulatory-compliant, audit-friendly system for full peace of mind | |

Can be set up for production and perform validation at the click of a button | User-friendly and compatible with a wide range of blister-packaging machines | |

Safety guards, emergency stop switches, and controlled access points | Ensures safe operation in production environments | |

Inspection reports capturing leak detection results, batch summaries, and quality trends | Enables auditing and process improvement |

Features & Benefits

Detects pinholes with diameters as small as 25 μm

Detection sensitivity is adjustable to suit user requirements

100% real-time inspection of pores, fissures and pinholes on lidding and base foils

Compatible with aluminium foils of different widths and lengths

Assured performance, irrespective of aluminium foil types and sizes

GMP-compliant

A regulatory-compliant, audit-friendly system for full peace of mind

Can be set up for production and perform validation at the click of a button

User-friendly and compatible with a wide range of blister-packaging machines

Safety guards, emergency stop switches, and controlled access points

Ensures safe operation in production environments

Inspection reports capturing leak detection results, batch summaries, and quality trends

Enables auditing and process improvement

Technical specifications

| Machine dimension (with standard mounting) | Length | 321 mm | |

| Width | 63 mm | ||

| Height | 323 mm | ||

| Inspection area (FOV) | 200 mm | ||

| Type of packaging material inspected | Aluminium foil (non-transparent) | ||

Also Available In

|

BACK TO ALL PRODUCTS

BACK TO ALL PRODUCTS