About the QUEST FB III X•ONE

Supreme safety with ultimate versatility – that’s what you get with the FBC X•ONE series developed at our Design Centre in Mülheim, Germany. While you can use it for diverse applications, including drying, top-spray granulation and Wurster coating, its cutting-edge design and features don’t compromise process or operator safety. In short, you get the very best outcomes and unbeatable protection.

A strong foundation for scale-up and design of experiments (DoE) studies, our QUEST FB III X•ONE is a versatile, intermediate-scale fluid-bed system featuring all aspects of typical commercial-scale equipment. This means you can establish process parameters quickly and accurately, and be confident scaling up your batches.

Applications

Drying, hot-melt granulation, Wurster coating, top-spray, tangential-spray and rotor granulation

| Features | Benefits | |

|---|---|---|

A 12-bar pressure shock resistant system featuring the MOST™ (Maximum Operator Safety Technology) concept approved by ATEX and certified by FSA | No mechanical deformation caused in case of a pressure-shock event

Far safer for the environment, thanks to a non-vented, fully contained design | |

X•ONE inflatable seals | 12-bar-rated inflatable seals ensure safety at pressures as low as 4.5 bar

Lower operating costs and significantly longer lifespan | |

State-of-the-art twin-filter bag-shaking system | Most efficient way of removing sticky materials which prevents filter choking, thereby improving overall filter performance

Enhances yield significantly while maintaining lower compressed air consumption | |

ACG’s exclusive process control system | Compliant with ATEX, GAMP 5 and 21 CFR Part 11, this advanced technology allows intuitive, secure monitoring and control | |

Fully integrated multi-function column | Reduces maintenance downtime and operational costs

The smart open-profile column has removable covers for swift and simple access to integrated peripherals, while a linear drive makes raising and lowering the exhaust air filter far easier

The control panel and keyboard are adjustable to operator preference |

Features & Benefits

A 12-bar pressure shock resistant system featuring the MOST™ (Maximum Operator Safety Technology) concept approved by ATEX and certified by FSA

No mechanical deformation caused in case of a pressure-shock event

Far safer for the environment, thanks to a non-vented, fully contained design

X•ONE inflatable seals

12-bar-rated inflatable seals ensure safety at pressures as low as 4.5 bar

Lower operating costs and significantly longer lifespan

State-of-the-art twin-filter bag-shaking system

Most efficient way of removing sticky materials which prevents filter choking, thereby improving overall filter performance

Enhances yield significantly while maintaining lower compressed air consumption

ACG’s exclusive process control system

Compliant with ATEX, GAMP 5 and 21 CFR Part 11, this advanced technology allows intuitive, secure monitoring and control

Fully integrated multi-function column

Reduces maintenance downtime and operational costs

The smart open-profile column has removable covers for swift and simple access to integrated peripherals, while a linear drive makes raising and lowering the exhaust air filter far easier

The control panel and keyboard are adjustable to operator preference

Technical specifications

| Working volume* | Top-spray granulation | Wurster coating | |

| Min | 12 l | 5 l | |

| Max | 55 l | 25 l |

*Dependent on bulk density

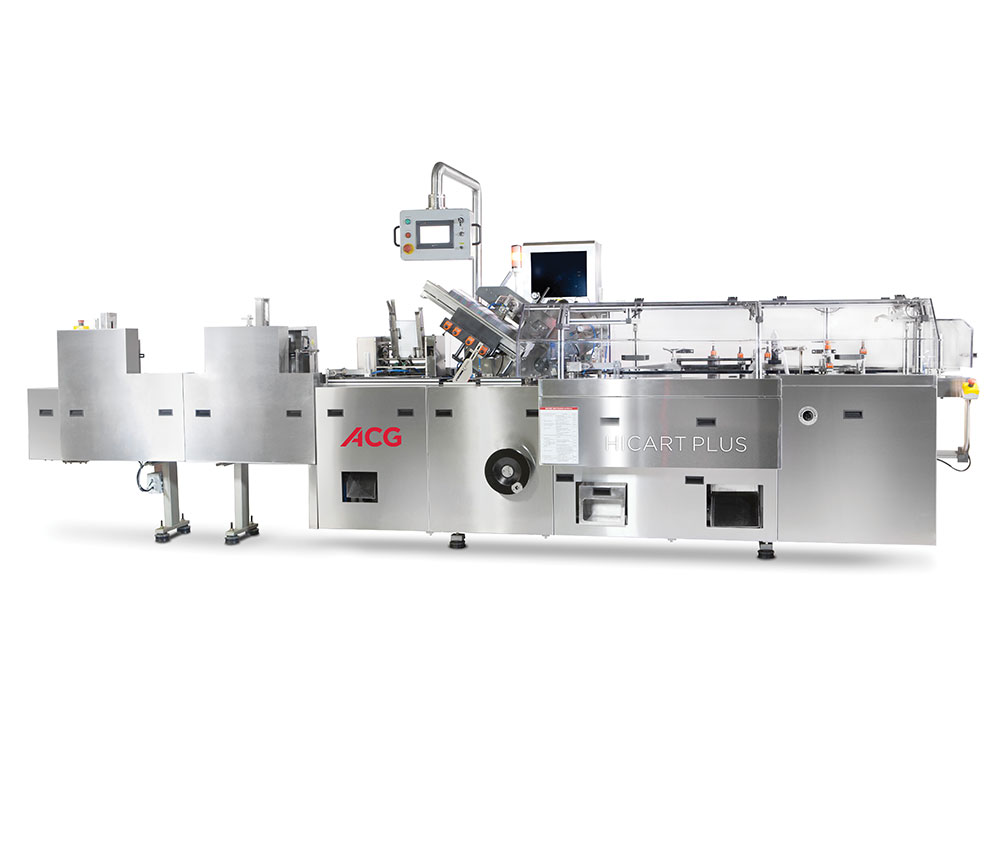

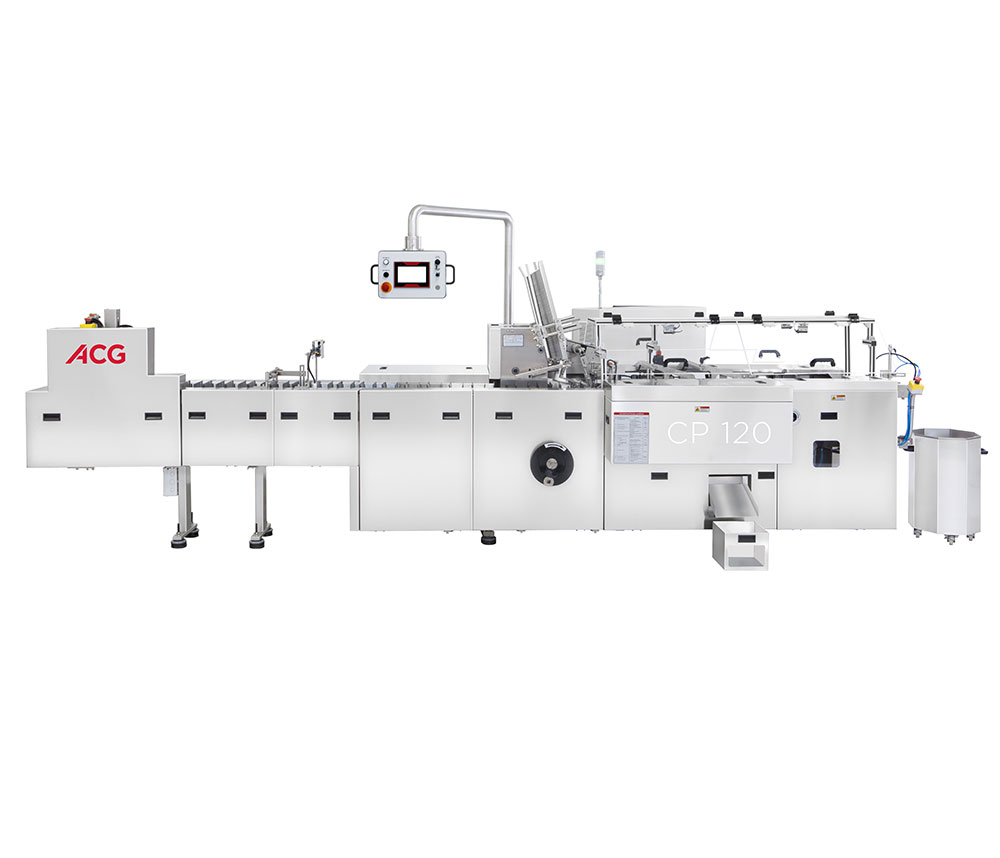

Also Available In

|

Related products

Always getting better at helping make people better.

BACK TO ALL PRODUCTS

BACK TO ALL PRODUCTS