About the QUEST FB I

Our versatile FBC range expands your process efficiency exponentially. With your need for flexible operations in mind, we designed our combo series to feature top-spray and Wurster coating technology in one innovative machine. It’s a proven boost for the pharmaceutical and nutraceutical industries.

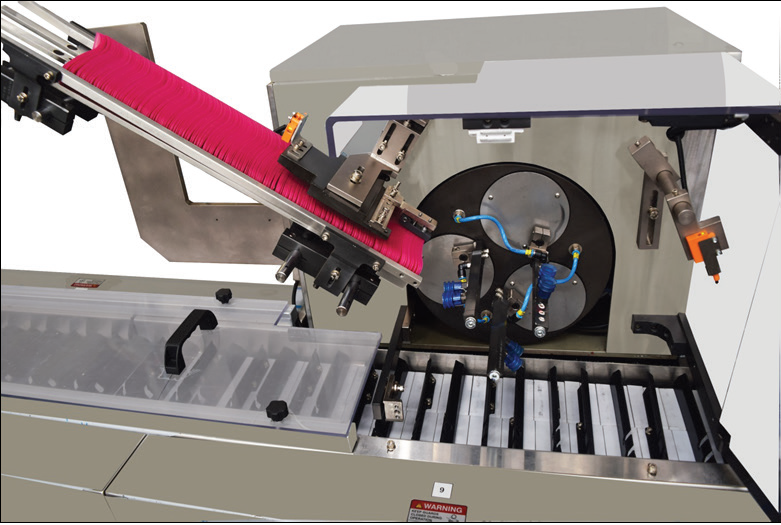

QUEST FB I is a lab-scale fluid-bed system that champions safety and precision, and it's the perfect choice for pharmaceutical feasibility studies. It features a certified 12-bar pressure shock-resistant design, with a versatile Schlick spray nozzle for both granulation (top-spray) and Wurster coating processes.

Mounted on a mobile trolley platform and measuring just 1 m x 1.2 m, it’s ideal for labs – saving space while achieving optimum functionality.

Applications

Drying, Wurster coating, top-spray and hot-melt granulation

| Features | Benefits | |

|---|---|---|

A 12-bar pressure shock-resistant system featuring the MOST™ (Maximum Operator Safety Technology) concept | Ensures 100% operator and environment safety, thanks to its non-vented, fully contained design | |

Unique proprietary dual-purpose Schlick spray nozzle | Single nozzle for granulation (top-spray) and pellet coating (Wurster coating) processes | |

Heating system with face and bypass mechanism | Precise and quick process-temperature control for consistent product quality | |

Expansion chamber with 360° sight glass | Facilitates easy monitoring of the fluidisation process | |

Integrated peristaltic pump | Precise control over spray rates via human-machine interface (HMI) |

Features & Benefits

A 12-bar pressure shock-resistant system featuring the MOST™ (Maximum Operator Safety Technology) concept

Ensures 100% operator and environment safety, thanks to its non-vented, fully contained design

Unique proprietary dual-purpose Schlick spray nozzle

Single nozzle for granulation (top-spray) and pellet coating (Wurster coating) processes

Heating system with face and bypass mechanism

Precise and quick process-temperature control for consistent product quality

Expansion chamber with 360° sight glass

Facilitates easy monitoring of the fluidisation process

Integrated peristaltic pump

Precise control over spray rates via human-machine interface (HMI)

Technical specifications

| Top-spray granulation | Wurster coating | ||

| Working volume* | Min | 0.6 l | 0.3 l |

| Max | 3 l | 1.5 l | |

*Dependent on bulk density

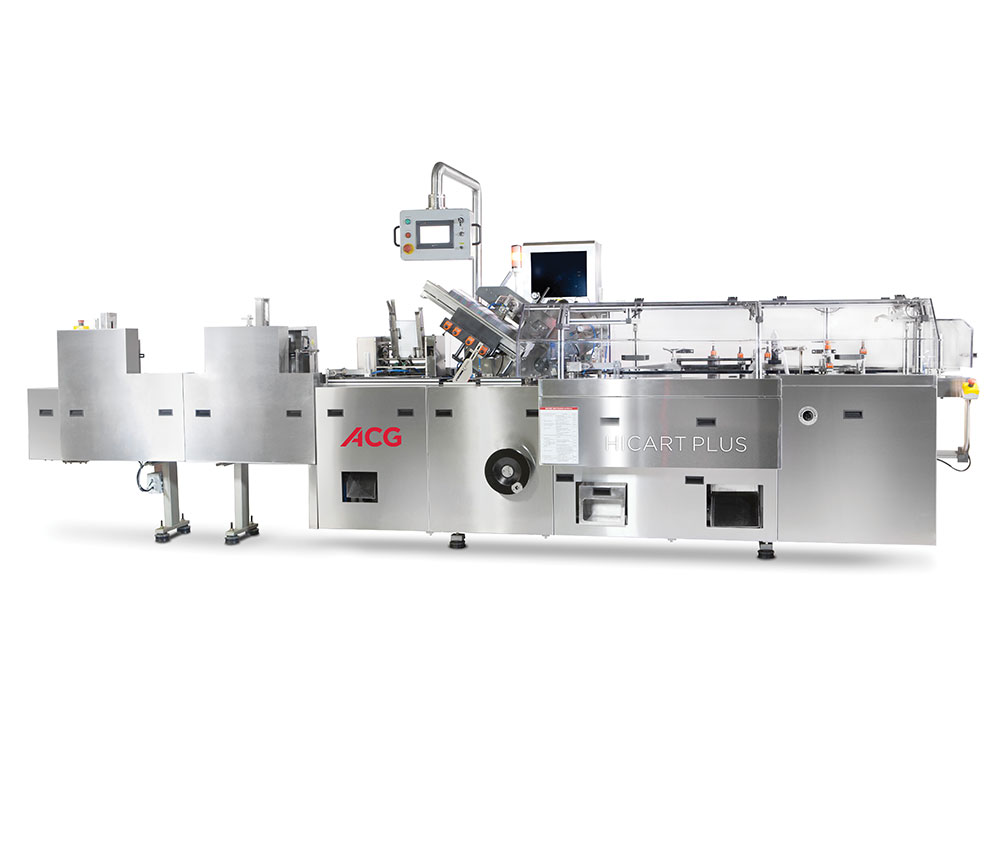

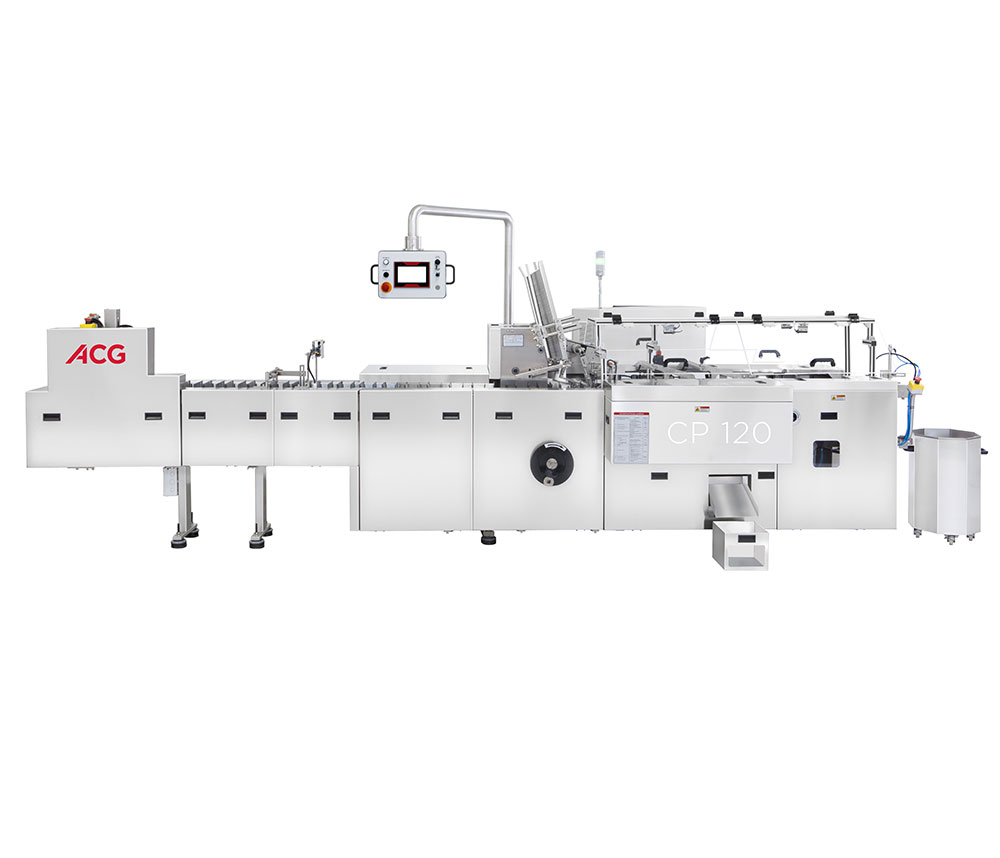

Also Available In

|

Related products

Always getting better at helping make people better.

BACK TO ALL PRODUCTS

BACK TO ALL PRODUCTS