About the VISITAB 3-M

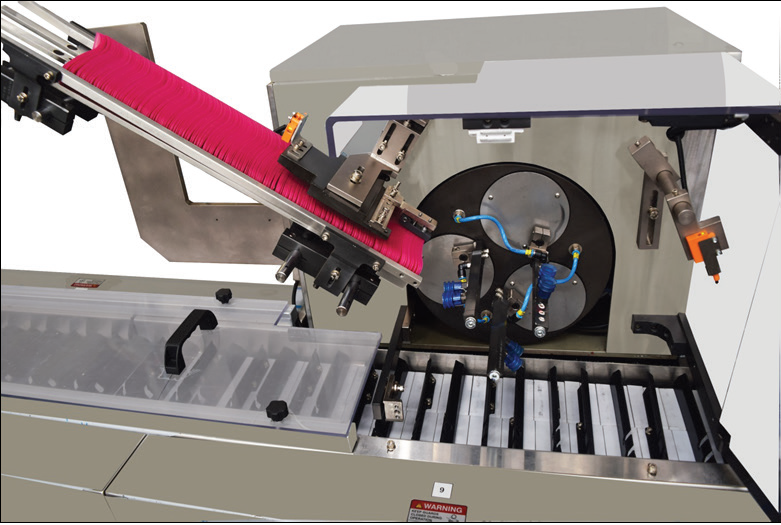

The VISITAB series consists of fully automatic, high-speed, customisable inspection machines. They are capable of high-volume inspection of tablets and capsules, and the accurate detection of even the smallest visual defects. These high-output inspection machines ensure 360° inspection of tablets and capsules, offering unparalleled inspection with no-compromise precision.

VISITAB 3-M offers the highest-quality tablet inspection, with new-generation colour camera and Blu-ray laser technology. It’s a vision-based turnkey system designed in compliance with pharmaceutical industry requirements for quality control of tablets.

Applications

Inspection of tablets

| Features | Benefits | |

|---|---|---|

10 new-generation colour cameras per track with diffuse lighting and inspection angles specially optimised for tablets | A multi-view system covering top, bottom, lateral, and edge areas of tablets guaranteeing 360° inspection for all cosmetic defects | |

Two 3D high resolution laser sensors per track for improved laser vision | Accurate tablet surface analysis covering cracks, embossment, thickness defects, coating, and engraving integrity | |

High-speed inspection | Sorts up to 600,000 tablets per hour | |

All format parts included for tablet feeding | Plug-and-play tooling that needs low-volume storage | |

Two high-speed vacuum tracks with anti-jamming feeding mechanism | Feeds complex-shaped tablets, including flat and semi-convex tablets ranging from 5mm width/diameter to 13 mm width/diameter | |

Intuitive configuration with template-based set-up and automatic learning system | Easy to use and can be set-up in 30 minutes | |

21 CFR Part 11-compliant | Regulatory compliant, audit-friendly system |

Features & Benefits

10 new-generation colour cameras per track with diffuse lighting and inspection angles specially optimised for tablets

A multi-view system covering top, bottom, lateral, and edge areas of tablets guaranteeing 360° inspection for all cosmetic defects

Two 3D high resolution laser sensors per track for improved laser vision

Accurate tablet surface analysis covering cracks, embossment, thickness defects, coating, and engraving integrity

High-speed inspection

Sorts up to 600,000 tablets per hour

All format parts included for tablet feeding

Plug-and-play tooling that needs low-volume storage

Two high-speed vacuum tracks with anti-jamming feeding mechanism

Feeds complex-shaped tablets, including flat and semi-convex tablets ranging from 5mm width/diameter to 13 mm width/diameter

Intuitive configuration with template-based set-up and automatic learning system

Easy to use and can be set-up in 30 minutes

21 CFR Part 11-compliant

Regulatory compliant, audit-friendly system

Technical specifications

| Tablet sizes that can be inspected (diameter/width) | 5 - 13 mm |

| Rated output | Up to 600,000 tablets/hr |

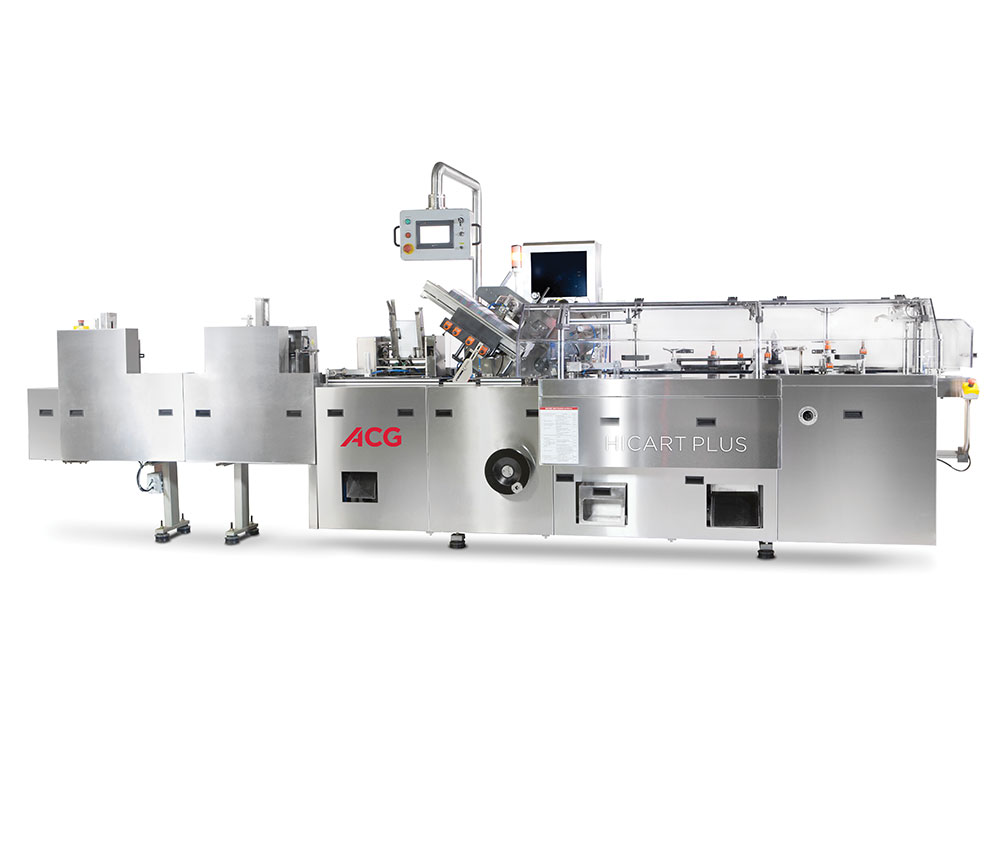

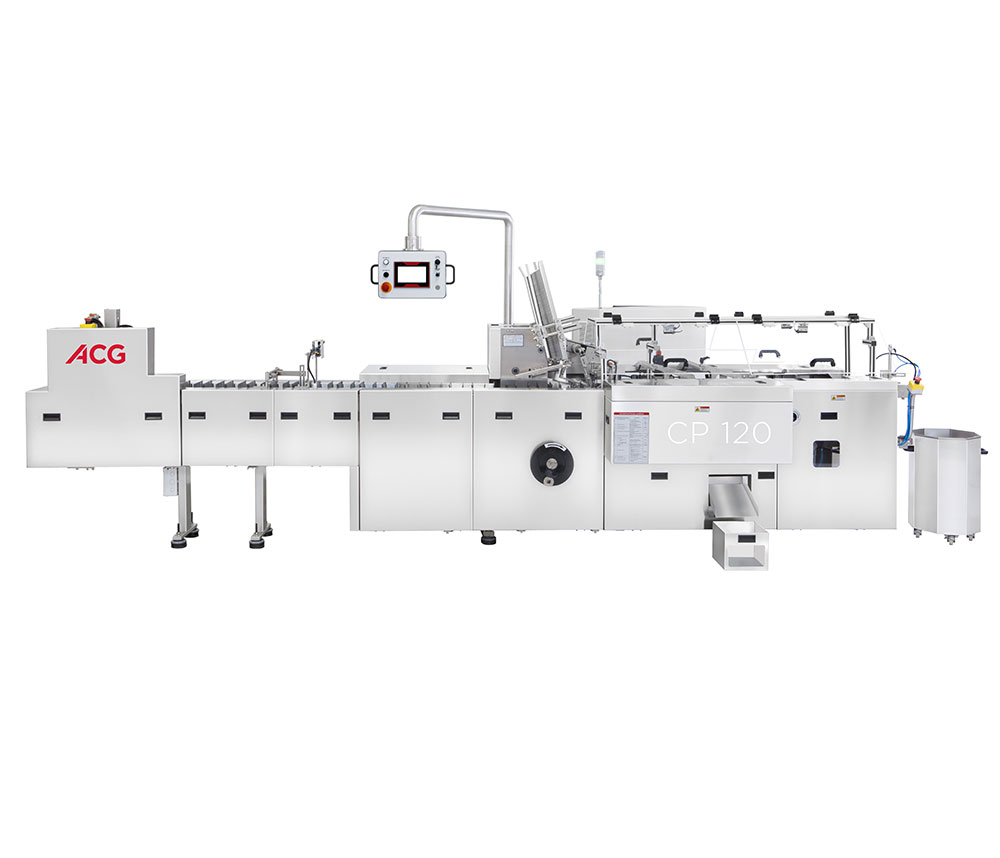

Also Available In

|

BACK TO ALL PRODUCTS

BACK TO ALL PRODUCTS