When it comes to tablet compression, the significance of quality and precision cannot be overstated.

That’s why we’ve extended our six decades of expertise in precision engineering to the design and manufacture of high-end tablet tooling.

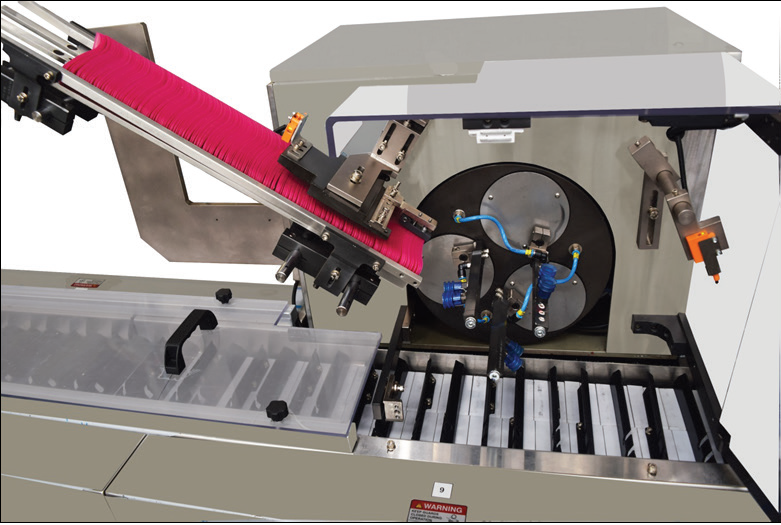

Our 23,000 sqm facility dedicated to component manufacturing covers capabilities for conducting metallurgical studies, heat treatment, CNC manufacturing, plating, coating, and testing dies and punches.

Why choose ACG’s tablet tooling?

- High-quality steels and manufacturing standards, as per TSM and EU

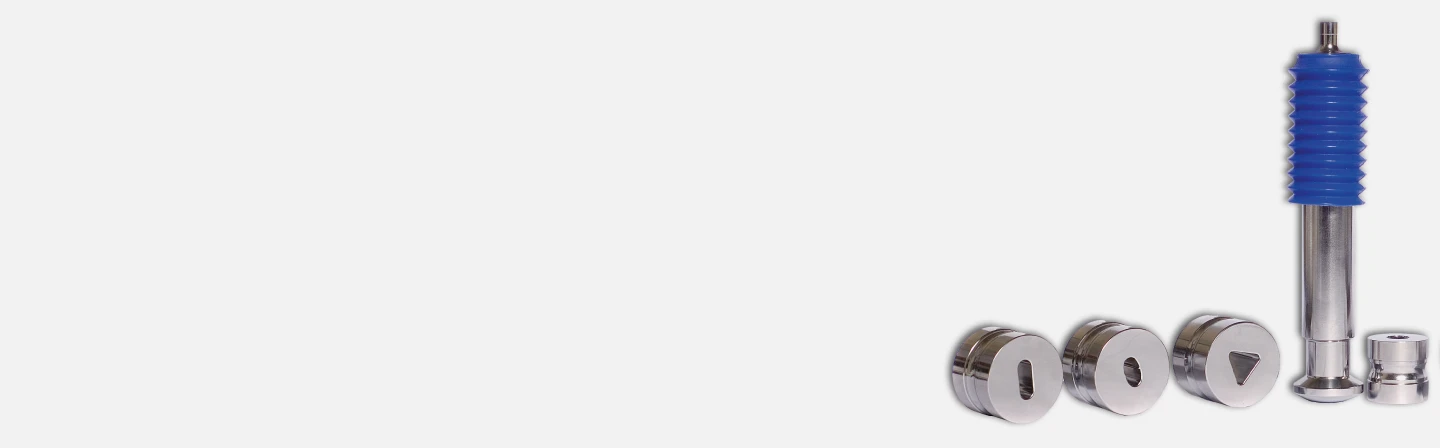

Our punches and dies are designed using the latest industry-benchmarked 3D software, and manufactured with close tolerances commensurate with various OEM tablet press designs – using an array of surface treatments compatible with substrate metallurgy. We source our raw materials only from qualified vendors with rigorous quality assurance systems in place. All of this ensures our punches and dies are durable, efficient, and consistent in their performance.

- Customisation options

Our expertise lies in enabling customisations as envisioned in the end-dosage design, and in choosing the base material and coating most suitable for maintaining tablet quality and repeatability of parameters.

- Fast turnaround times

We understand time is precious, so we ensure fast turnaround times to ensure your tablet production processes stay on schedule.

- Superior customer support

Our team is always available to answer your questions, and we’re keen to collaborate with you through design and development, to validation

and documentation.

Our seal of trust and integrity

With stringent adherence to specified tolerance limits, we perform rigorous metallurgical and chemical checks in-house, including:

- a host of NDTs (non-destructive tests) on raw materials before manufacturing

- micro-structure analysis after heat treatment

We follow the globally recognised TSM and the Euronorm (EU) tooling standards for manufacturing our dies and punches.

Specialised heat-treatment

Tablet tooling quality depends on the composition of the steel grade and its heat-treating, among other factors. The heat-treating process is a critical step in the manufacture of tooling, and gives steel the hardness that determines wear and impact resistance.

ACG performs heat-treatment in-house using a computer-controlled process that secures the desired steel microstructure and guarantees the durability and longevity of our tablet tooling.

Triple tempering - the final step of our heat-treatment cycle - ensures uniform hardness throughout a tooling set.

Our tooling. Your tablets.

Our extensive tablet tooling portfolio covers a wide range of customised tooling, plus specialist options for complex coatings and heat treatment. We also manufacture a wide range of standard tooling, including D, B, BB, and BBS types.

Specialised coatings

To enhance tooling performance, ACG offers a wide range of coatings. Our experience with hundreds of formulations ensures we can address your specific needs for coatings – for example, if you work with corrosive, abrasive or sticky formulations.

Designer tooling

ACG can expertly develop customised punches and dies to suit specific requirements, to support brand differentiation and stand-out, and to introduce or enhance anti-counterfeiting measures.

Multi-tip tooling

Unlike traditional single-tip tooling, a multi-tip tool offers several tips in a single punch. This supports production of multiple tablets per turret rotation, enhancing productivity and saving time and costs. You can also use multi-tip tooling for manufacturing mini tablets (< 4.5 mm diameter) to be contained in capsules, to facilitate dosage combinations with different release profiles.

Always getting better at helping make people better.

BACK TO ALL PRODUCTS

BACK TO ALL PRODUCTS