Packaging plays a critical role in safeguarding pharmaceutical products from the detrimental effects of ambient air and moisture, thereby extending their shelf life. However, it's worth noting that, beyond its protective function, superior packaging can help secure a genuine and compelling differentiation. And at ACG, we’re acutely attuned to the contemporary demands of achieving shelf prominence and establishing a resilient brand identity in a crowded and competitive market.

That's why we've sold well over 10,000 format parts to the global pharmaceutical industry, facilitating the seamless customisation of packaging solutions across a diverse array of formats, accommodating varying product shapes and sizes.

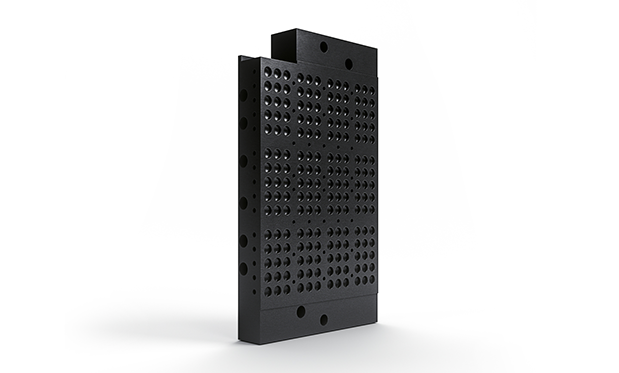

The key lies in using format parts made by original equipment manufacturers (OEMs) is essential, because they’re designed to fit specific machinery perfectly. As a result, they are longer wearing, ensuring greater lifecycles, consistent productivity, and the highest overall efficiency of your equipment.

Original manufactured parts – a wise investment

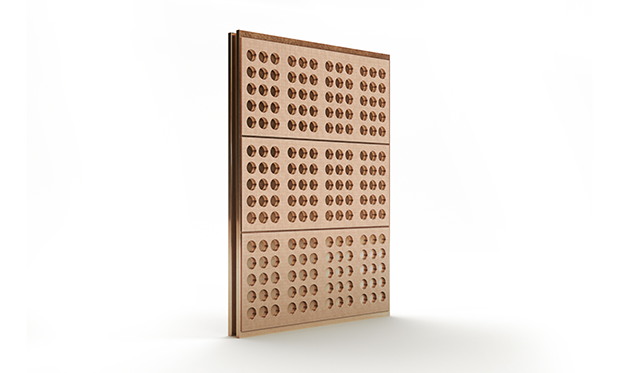

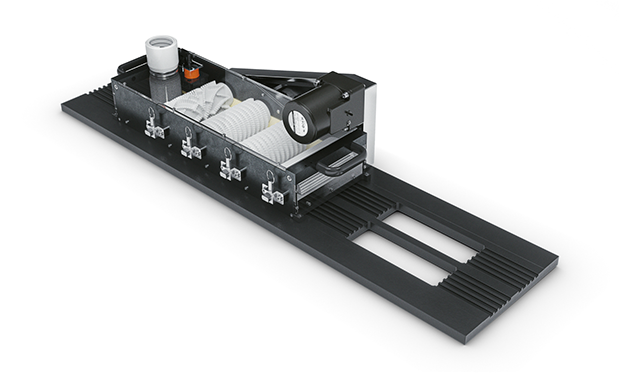

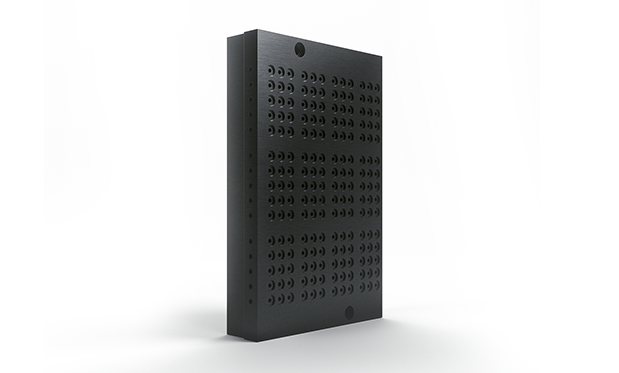

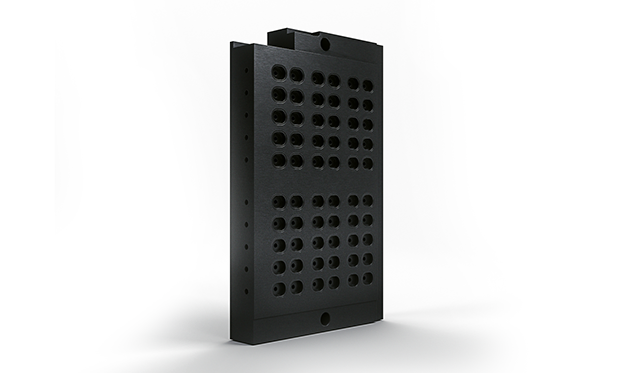

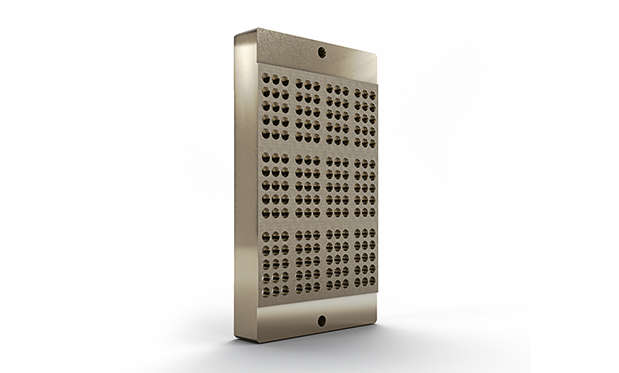

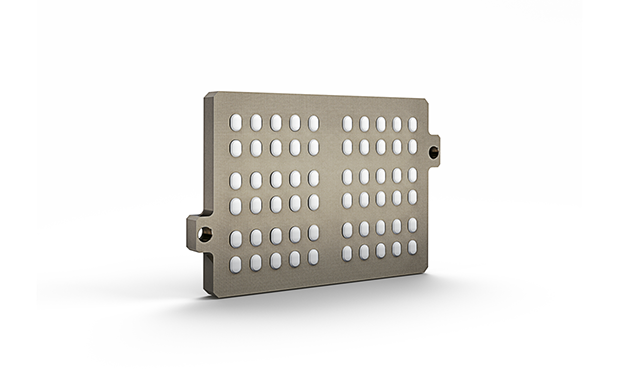

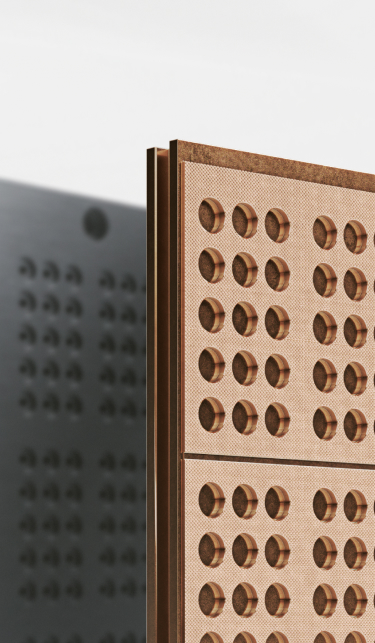

ACG blister format parts are produced to the highest quality standards. As OEMs of many of the industry’s top blister packaging machines – including our highly acclaimed BQS – our parts are the best fit, by far.Every single blister format part is tailor-made to your production requirements and uses only the highest quality materials. With the high-quality raw materials and cutting-edge machines we insiston, we can assure you the highest tolerances and standards.

Pre-tested and ready to go

Every single part that leaves our world-class facilities has passed a series of rigorous quality tests before dispatch. And because we test them on the very machines they’re made for, you know you can use them straight from the box.Of course, all format parts come with comprehensive service support to ensure your machine functions smoothly, for longer.

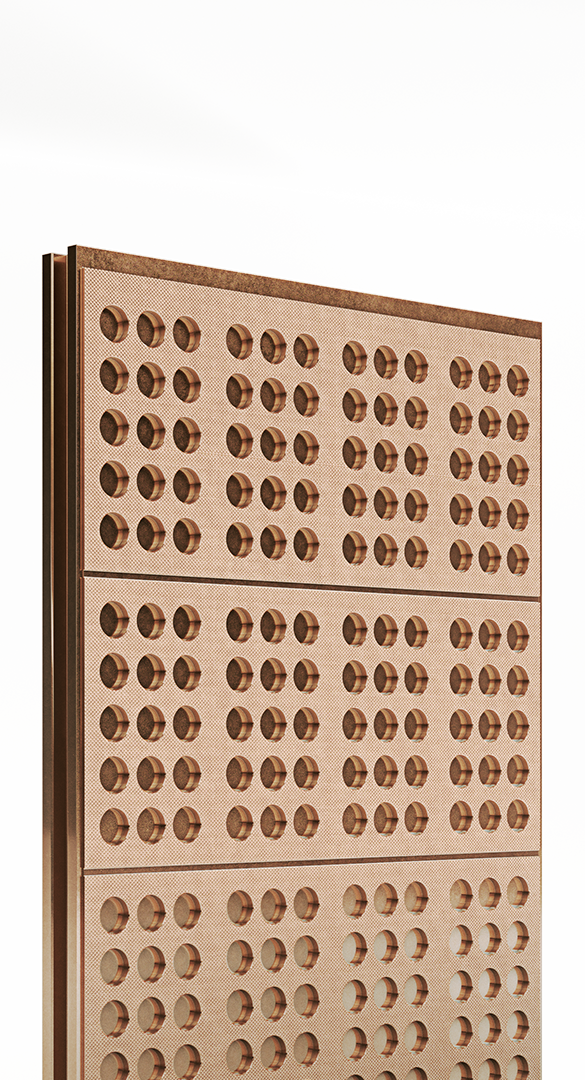

Our quality alloy seals 4x better

Our proprietary alloy Better Seal™, used in the sealing plate of format parts, conducts heat four times faster than stainless steel. That ensures more uniform sealing and fewer rejects.Better Seal™ is proven to have a temperature control 33% better than stainless steel plates. This means you can expect far fewer high-temperature alarms in your production run, while some customers have saved as much as 6.5 hours production time. That’s almost an entire shift!

Always getting better at helping make people better.

BACK TO ALL PRODUCTS

BACK TO ALL PRODUCTS