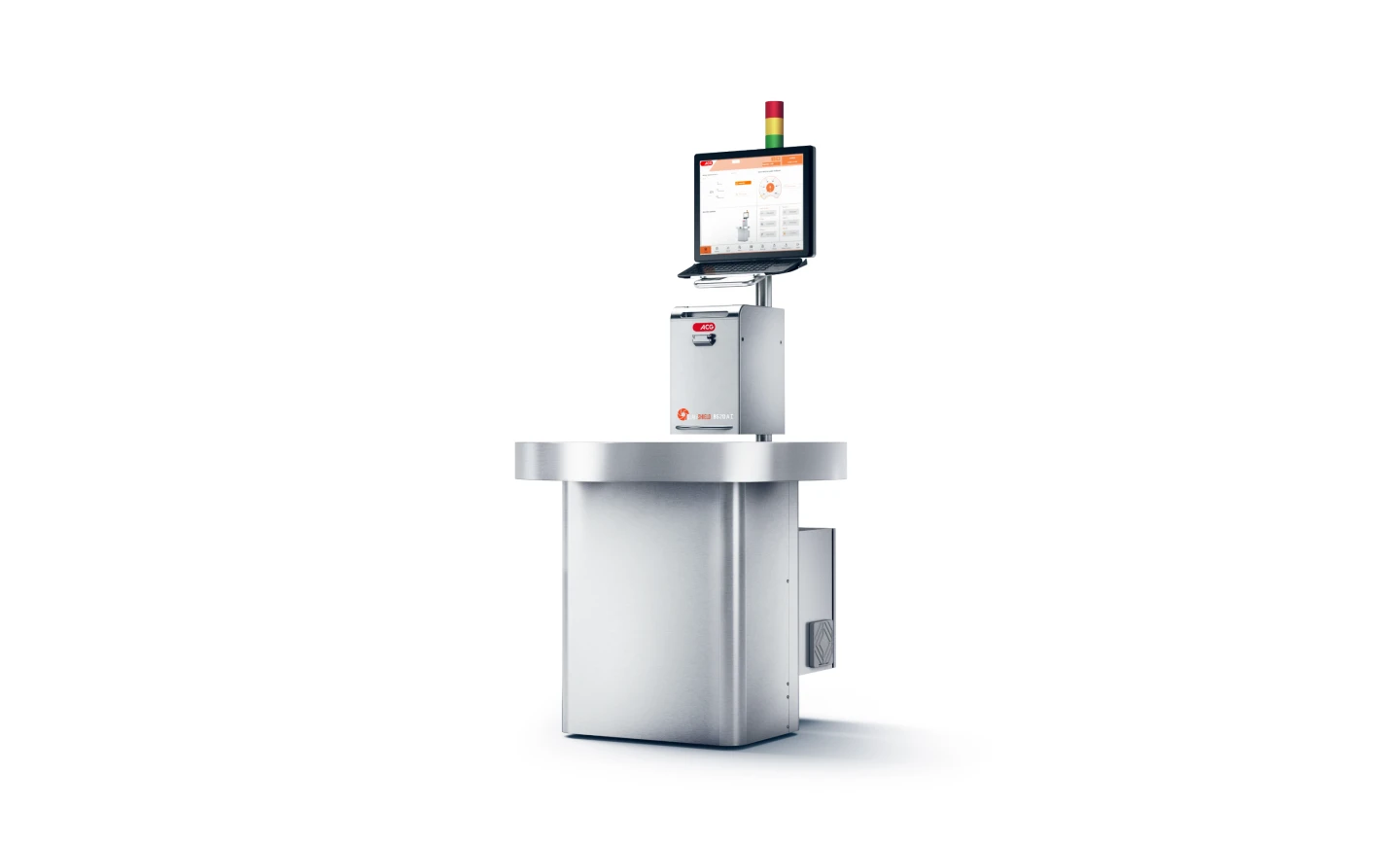

The QualiShield® BS12 AI is a compact, AI-driven blister inspection system designed to integrate seamlessly with various blister-packaging machines. It detects a full range of potential product defects in blister packs, ensuring compliance with stringent quality standards. The BS12 supports the integration of multiple cameras within a single controller, plus an additional camera for barcode, pharmacode, or batch-detail inspection.

Unlike conventional systems that rely on threshold-based image processing with high dependency on product-foil contrast, QualiShield® BS12 AI works on sophisticated anomaly detection algorithms. By removing such dependency, this AI-powered system delivers superior inspection reliability across diverse packaging materials and product types. By automating inspection and learning from production data, it maximises efficiency, minimises product defects, and reduces the risk of costly recalls.

Application

Missing tablets or capsules, broken or chipped products, foreign matter, colour variation, improper placement, and sealing defects in formed and sealed blisters

| Features | Benefits | |

|---|---|---|

| Advanced AI/ML capabilities that help in the automatic pocket detection within the field of view (FOV) and threshold range detection | Significantly lower ‘teaching’ time | |

| User-friendly GUI with multiple language support | Easy to access and user-friendly | |

| Categorised representation of rejection quantities | Summarises large datasets in accessible visual formats | |

Integrated safety enclosures, emergency stop mechanisms, and access interlocks | Safeguards operators during continuous high-speed inspection | |

Comprehensive batch and defect reports with image capture, defect categorization, and trend analysis | Detailed audits and thorough quality assurance | |

Configurable user rights, 21 CFR part 11 and EU Annex 11 compliant | A regulatory-compliant, audit-friendly system | |

| Plug-and-play installation | Quick and error-free installation |

Features & Benefits

Integrated safety enclosures, emergency stop mechanisms, and access interlocks

Safeguards operators during continuous high-speed inspection

Comprehensive batch and defect reports with image capture, defect categorization, and trend analysis

Detailed audits and thorough quality assurance

Configurable user rights, 21 CFR part 11 and EU Annex 11 compliant

A regulatory-compliant, audit-friendly systemTechnical specifications

| FOV (Field of view) | 240 mm x 150 mm |

| Maximum speed | 200 inspections/min |

| Product types inspected | Single and multi-coloured tablets Single and multi-coloured capsules Printed capsules (single and multi-colour) Printed tablets Soft gelatin capsules |

| Base foil types inspected | Clear PVC Opaque PVC Coloured PVC Aluminium foils |

| Defects detected | Missing product Double product Spots on product Different shape or shade Foreign particles or powder with product Cracked, chipped or broken tablets Double capping in capsule Powder in cavity |

BACK TO ALL PRODUCTS

BACK TO ALL PRODUCTS