Better manufacturing makes it better.

At ACG, we understand that although we’re in the business of making pharmaceutical equipment, we’re actually about saving lives and keeping people healthy. That’s why we take our machines so seriously.

This means that when you buy ACG equipment (any ACG equipment) you can trust it’s been made with utmost care and consideration – from innovative design, to quality materials, to having the most exacting production standards. As part of the package, you also receive best-in-class aftermarket service and customer support, along with sixty years of pharmaceutical manufacturing expertise and advice.

Our ranges include almost everything required to process and pack solid dosage medications. We are also willing to customise our machines and systems (wherever possible) to even better suit your needs.

ACG Laboratory for Process Development

Here whenever you need one.

In February 2021, ACG inaugurated a Process Development Laboratory in Shirwal, India. Dedicated to the collaborative pursuit of making the world healthier, here customers can come and co-create with ACG experts in all aspects of process development, while gaining access to some of the world’s newest and most innovative pieces of laboratory equipment. We believe magic happens when people come together in a spirit of partnership.

ACG aftermarket service and sales

Aftermarket. Not afterthought.

At ACG, we understand that when you get a new piece of factory equipment, you’re buying far more than a machine; you’re also investing in a relationship that will last its lifetime. That’s why we take our aftermarket service so seriously. Whether you need advice or training, are preparing to make your factories ‘smarter’, or simply need a machine fixed fast, know that ACG will always go above and beyond to offer excellent service and value. As far as we’re concerned, we’re in this together – for life.

ACG Smart Connected

Helping machines find their voice.

With ACG Smart Connected, you can remotely track your assets with real-time visibility and monitoring, as well as diagnose problems on your machines and improve overall equipment efficiency (OEE). A simple adaptor kit converts existing analogue ACG machines into talking ones… it couldn’t be easier.

Global design

Our machines are designed on three continents.

ACG supports a multi-national team of pharmaceutical equipment designers and developers, with parties contributing different perspectives, ideas and schools of thought. Alongside its own German process development team, ACG regularly collaborates with equipment designers in France, Italy, the USA, India, and Croatia.

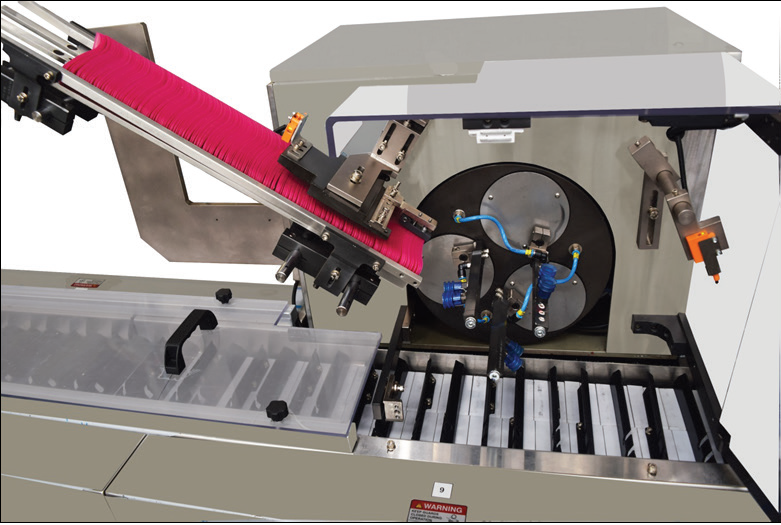

ACG blister inspection

Highly intelligent.

ACG’s blister inspection systems incorporate AI technology, providing a quantum leap forward in defect detection accuracy – especially with low contrast product and foil combinations. Training the system requires almost zero human involvement, and the machine keeps learning new behaviours from itself (deep learning). Existing machines can even be used to train new ones.