Header text

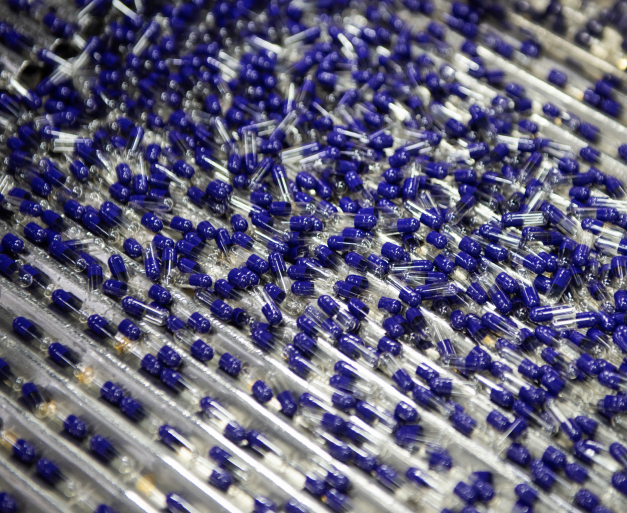

Blister packs remain a popular packaging type for solid oral dosage formulations. However, when it comes to packaging of oxygen-reactive and hygroscopic pharmaceutical products, blisters provide inadequate protection from environmental factors; therefore, other measures are required.

When a leading pharmaceutical company approached us for a secure packaging solution for their oxygensensitive product, we recommended blister packaging using nitrogen enhanced purging (NEP) to maximize product stability.

Text here

Header using nato sans

In the pharmaceutical industry, blister packaging is frequently preferred because of its convenience, high patient compliance, and cost-effectiveness. Their unique design allows blister packs to offer individual unitdose compartments, along with tamperevident features that ensure product security. However, blister packaging of oxygenreactive and hygroscopic products needs special consideration.

Although high-barrier thermoform film and aluminum foil blisters can provide a certain degree of protection against unwanted moisture and oxygen ingress, this may not offer complete protection against headspace moisture, gases, and impurities especially for moisture and oxygen-sensitive formulations. In such cases, NEP is a desirable method to increase the shelf-life of a product inside a blister pack.

The NEP system is designed for easy-to-use single-point purging of air from the blister cavities, replacing it with dry nitrogen. That is why, when our client wanted to pack an air-sensitive product into blisters, ACG helped them by providing a NEP system on their B MAX packaging machine.

Client profile

Challenge

The client approached us to provide them with a retrofit solution that would enable packaging of a highly oxygen-reactive and hygroscopic product from clavulanate and amines family using the B MAX blister packaging machine, which was already in operation at their site.

ACG Solution

ACG Solution Our team of expert designers and engineers worked on a system to add dry nitrogen into the blister cavities, thus flushing out moist air. The B MAX machine was provided with a NEP unit attachment, which injected dry nitrogen into the blister pack before sealing. This unit comprised a nitrogen cylinder/reservoir with gauges and a regulator attached to the nitrogen chamber. Depending on the requirements, the nitrogen pressure can be adjusted (0.1 - 4.5 bar) and the gas can be blown into the cavities to flush out air and replace it with the required amount of dry nitrogen.

The result

The addition of NEP enhanced the capability of the machine to facilitate packaging of oxygenreactive products into blister packs. A destructive test was performed to check the level of oxygen using an oxygen monitoring kit; no trace of oxygen was detected in the packed blister. This ensured the purity of the pharmaceutical product and extended its shelf-life.

57+

Borem ipsum dolor sit amet, consectetur adipiscing elit. Nunc vulputate libero et velit interdum, ac aliquet odio mattis. Class aptent taciti sociosqu ad litora torquent per.

100%

Borem ipsum dolor sit amet, consectetur adipiscing elit. Nunc vulputate libero et velit interdum, ac aliquet odio mattis. Class aptent taciti sociosqu ad litora torquent per.

1,050

Borem ipsum dolor sit amet, consectetur adipiscing elit. Nunc vulputate libero et velit interdum, ac aliquet odio mattis. Class aptent taciti sociosqu ad litora torquent per.