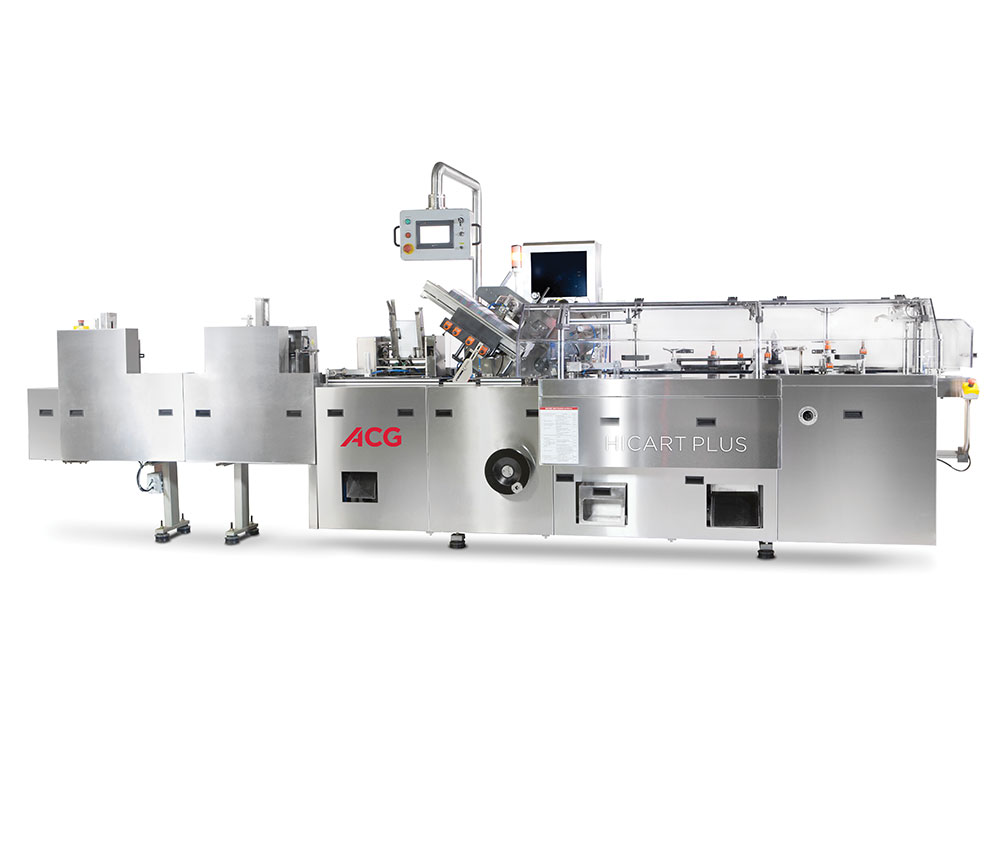

About the SMARTCOATER X•ONE series

Backed by more than 60 years of ACG engineering expertise, the SMARTCOATER X•ONE incorporates everything you need to ensure swift and economical processes – and uphold consistently high standards. As part of our new X•ONE series, and the next-level upgrade of ACG’s premium tablet-coating system, it makes tablet coating extraordinarily fast and fully reassuring, with increased process speed, efficiency and usability.

| Features | Benefits | |

|---|---|---|

Flexibility to work with 15 – 100% batch occupancy | Unique coating system that includes baffles, spray arms and drum | |

Accurate bed coverage for the entire batch size, and can be positioned to match all product requirements

| High-performing spray-arm design with full external control via infinity handle | |

No product build-up, so far easier to clean and maintain Easier handling | ACG’s X•ONE 2.0 Spray Nozzle developed in collaboration with Düsen-Schlick GmbH, Germany with an Anti-Bearding Cap – now 50% lighter | |

Dust-free, closed-door charging and 100% tablet discharge | Modular, automated and integrated design for tablet charging and discharging with inbuilt discharge baffles | |

Complete wetting of dead spots for faster, safer and efficient washing of all parts – including hard-to-reach corners | Advanced wash-in-place (WIP) technology featuring the optimum number and arrangement of nozzles | |

Compliant with ATEX, GAMP 5 and 21 CFR Part 11, this advanced technology allows intuitive, secure monitoring and control | ACG’s exclusive process control system |

Features & Benefits

Flexibility to work with 15 – 100% batch occupancy

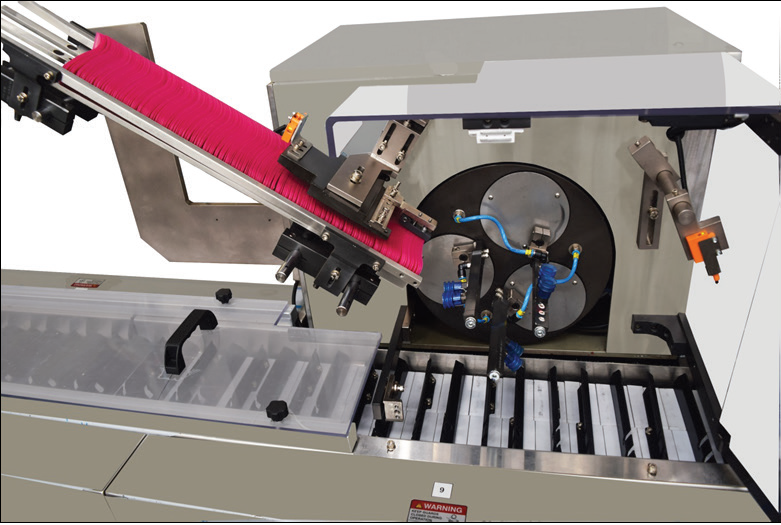

Unique coating system that includes baffles, spray arms and drum

Accurate bed coverage for the entire batch size, and can be positioned to match all product requirements

Avoids delays caused by in-process intervention

High-performing spray-arm design with full external control via infinity handle

No product build-up, so far easier to clean and maintain

Easier handling

ACG’s X•ONE 2.0 Spray Nozzle developed in collaboration with Düsen-Schlick GmbH, Germany with an Anti-Bearding Cap – now 50% lighter

Dust-free, closed-door charging and 100% tablet discharge

Modular, automated and integrated design for tablet charging and discharging with inbuilt discharge baffles

Complete wetting of dead spots for faster, safer and efficient washing of all parts – including hard-to-reach corners

Advanced wash-in-place (WIP) technology featuring the optimum number and arrangement of nozzles

Compliant with ATEX, GAMP 5 and 21 CFR Part 11, this advanced technology allows intuitive, secure monitoring and control

ACG’s exclusive process control system

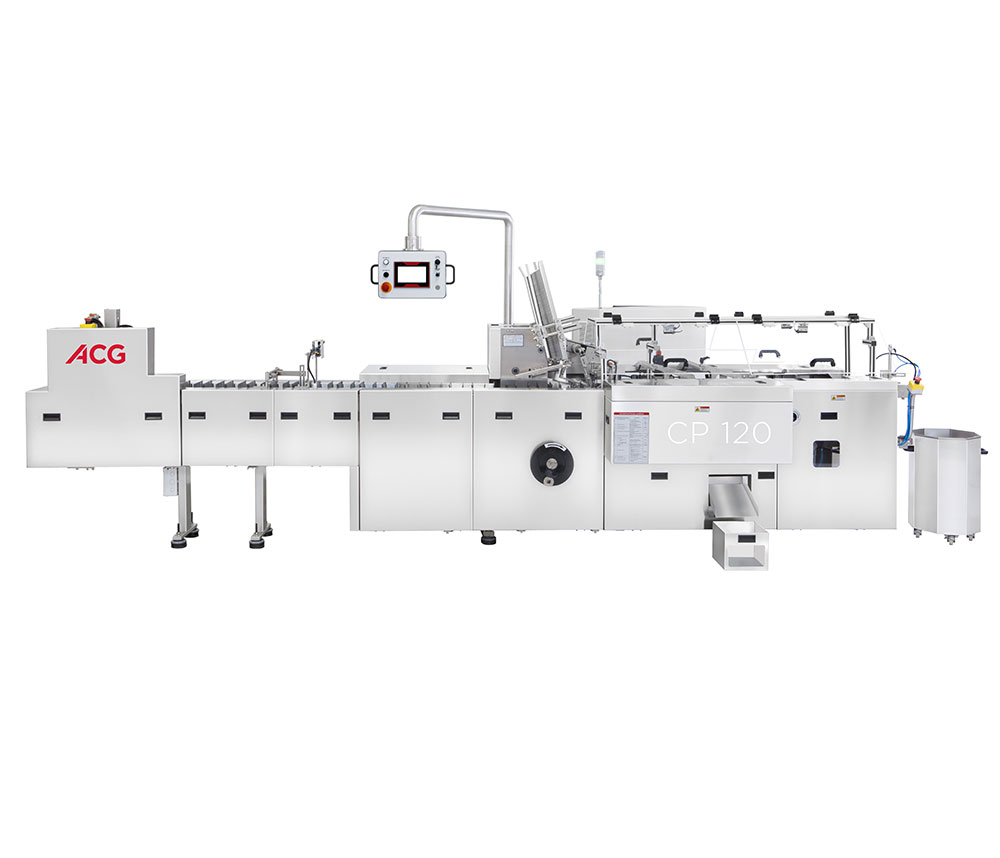

Also Available In

|

BACK TO ALL PRODUCTS

BACK TO ALL PRODUCTS