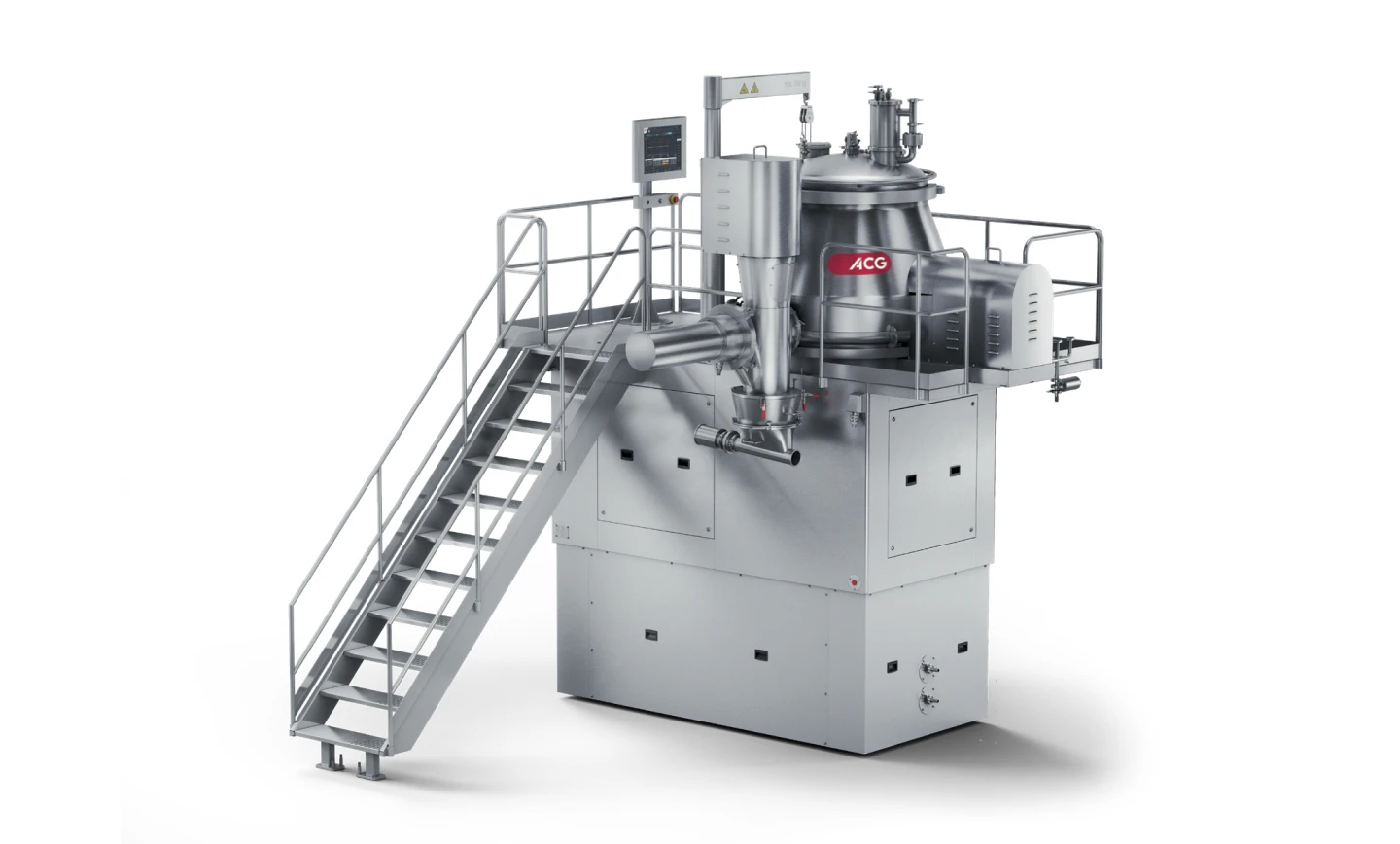

About the HSM series

An integral part of the granulation train, ACG’s High-Shear Mixer (HSM) is packed with innovative features and sets new standards of performance and adaptability in conventional processing equipment. Its advanced mixer/granulator technology guarantees efficient mixing, and ensures a high-quality end product.

With experience in handling over 1,000 formulations, our ACG Lab experts can help you with all aspects of process technology (including development, transfer, scale-up and optimisation) to achieve full efficiency and productivity.

Applications

Wet granulation, mixing, hot-melt granulation

| Features | Benefits | |

|---|---|---|

Ergonomic design of product bowl, with perfectly positioned access platform | Provides easy access to the machine and facilitates GMP compliance | |

Available with a Z-shaped impeller and multi-blade chopper | Superior centrifugal force avoids dead zones and achieves uniform binder distribution – thereby ensuring higher yield and optimal particle-size distribution | |

Multiple systems for charging and discharging, with a highly efficient vent air filtration system for wash-in-place (WIP) | Quick, dust-free transfer of raw materials, and easy washing | |

Integrated cleaning nozzles for product bowl and discharge | Makes cleaning much simpler |

Features & Benefits

Ergonomic design of product bowl, with perfectly positioned access platform

Provides easy access to the machine and facilitates GMP compliance

Available with a Z-shaped impeller and multi-blade chopper

Superior centrifugal force avoids dead zones and achieves uniform binder distribution – thereby ensuring higher yield and optimal particle-size distribution

Multiple systems for charging and discharging, with a highly efficient vent air filtration system for wash-in-place (WIP)

Quick, dust-free transfer of raw materials, and easy washing

Integrated cleaning nozzles for product bowl and discharge

Makes cleaning much simpler

BACK TO ALL PRODUCTS

BACK TO ALL PRODUCTS