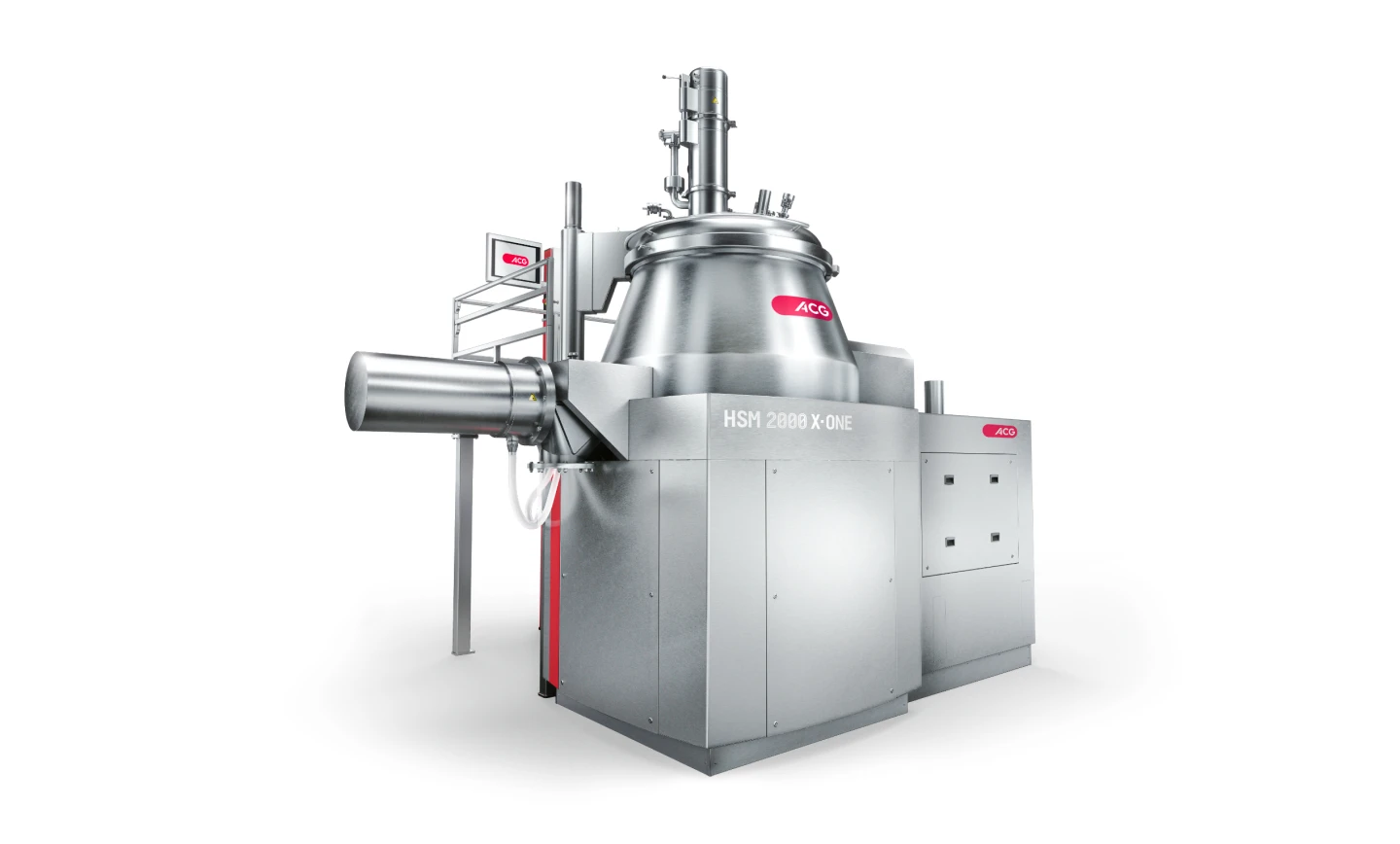

About the HSM 2000 X•ONE

An advanced series of high-shear mixer granulators that ensure faster processing and narrow particle-size distribution, while achieving content uniformity in the dry mix. The system is equipped with ACG's process control system and features the unique MOST™ (Maximum Operator Safety Technology) concept.

The HSM 2000 X•ONE is designed for large production batches and can be integrated fully into a granulation train or used as a standalone unit.

Applications

Wet granulation, mixing

| Features | Benefits | |

|---|---|---|

Unique product bowl geometry | Facilitates uniform mixing by maintaining a roping flow regime, and faster process stabilisation due to linear scalability features – ensuring optimum mixing efficiency | |

Designed with a Z-shaped impeller and multi-blade chopper | Achieves uniform binder distribution for higher yield and optimal particle-size distribution, minimising accumulation or sticking on the product bowl | |

A 12-bar pressure shock-resistant system featuring the MOST™ (Maximum Operator Safety Technology) concept approved by FSA in Germany and compliant with ATEX (Directive 2014/34/EU) | No mechanical deformation caused in case of a pressure-shock event

Production can be resumed in the shortest possible time

A far safer working environment, thanks to a non-vented, fully contained design | |

Multiple systems for charging, discharging and wash-in-place (WIP) | Unlocks greater flexibility to suit formulation needs | |

ACG’s exclusive process control system | Compliant with ATEX (Directive 2014/34/EU), GAMP 5 and 21 CFR Part 11, this advanced technology allows intuitive, secure monitoring and control of the system |

Features & Benefits

Unique product bowl geometry

Facilitates uniform mixing by maintaining a roping flow regime, and faster process stabilisation due to linear scalability features – ensuring optimum mixing efficiency

Designed with a Z-shaped impeller and multi-blade chopper

Achieves uniform binder distribution for higher yield and optimal particle-size distribution, minimising accumulation or sticking on the product bowl

A 12-bar pressure shock-resistant system featuring the MOST™ (Maximum Operator Safety Technology) concept approved by FSA in Germany and compliant with ATEX (Directive 2014/34/EU)

No mechanical deformation caused in case of a pressure-shock event

Production can be resumed in the shortest possible time

A far safer working environment, thanks to a non-vented, fully contained design

Multiple systems for charging, discharging and wash-in-place (WIP)

Unlocks greater flexibility to suit formulation needs

ACG’s exclusive process control system

Compliant with ATEX (Directive 2014/34/EU), GAMP 5 and 21 CFR Part 11, this advanced technology allows intuitive, secure monitoring and control of the system

Technical specifications

| Working volume* | Min | 600 l |

| Max | 1,600 l |

*Is dependent on the bulk density.

Also Available In

|

BACK TO ALL PRODUCTS

BACK TO ALL PRODUCTS