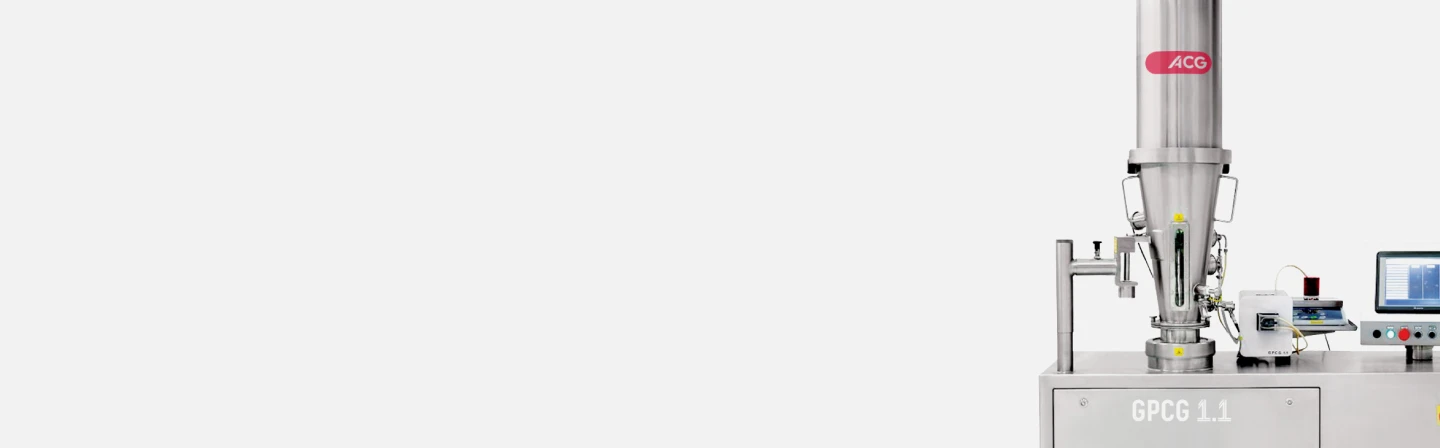

About the GPCG 1.1

Our versatile FBC expands your process efficiency exponentially. With your need for flexible operations in mind, we designed our combo series to feature top-spray and Wurster coating technology in one innovative machine. It’s a proven boost for the pharmaceutical and nutraceutical industries.

One of the workhorses in its performance class for feasibility and scale-up studies, the remarkably versatile GPCG 1.1 has all the features of a production-scale machine. Its capabilities include drying, granulation, particle/pellet coating, dry-powder layering, spray agglomeration and hot-melt granulation.

Applications

Top-spray granulation, wet-mass drying, hot-melt granulation, Wurster coating

| Features | Benefits | |

|---|---|---|

A mobile plug-and-play, standalone system with an optional integrated air-handling unit | Highly portable and user-friendly for quick switching across diverse applications | |

Filter bags with a shaking mechanism | Faster and more effective cleaning and handling | |

Multiple and interchangeable air-distribution plates | Select and install the plate that best suits your product, quickly and easily |

Features & Benefits

A mobile plug-and-play, standalone system with an optional integrated air-handling unit

Highly portable and user-friendly for quick switching across diverse applications

Filter bags with a shaking mechanism

Faster and more effective cleaning and handling

Multiple and interchangeable air-distribution plates

Select and install the plate that best suits your product, quickly and easily

Technical specifications

Top-spray granulation | Wurster coating | RGPCG | ||

| Working volume | Min | 1.4 l | 0.5 l | 1.5 l |

| Max | 4.7 l | 2.4 l | 4 l |

BACK TO ALL PRODUCTS

BACK TO ALL PRODUCTS