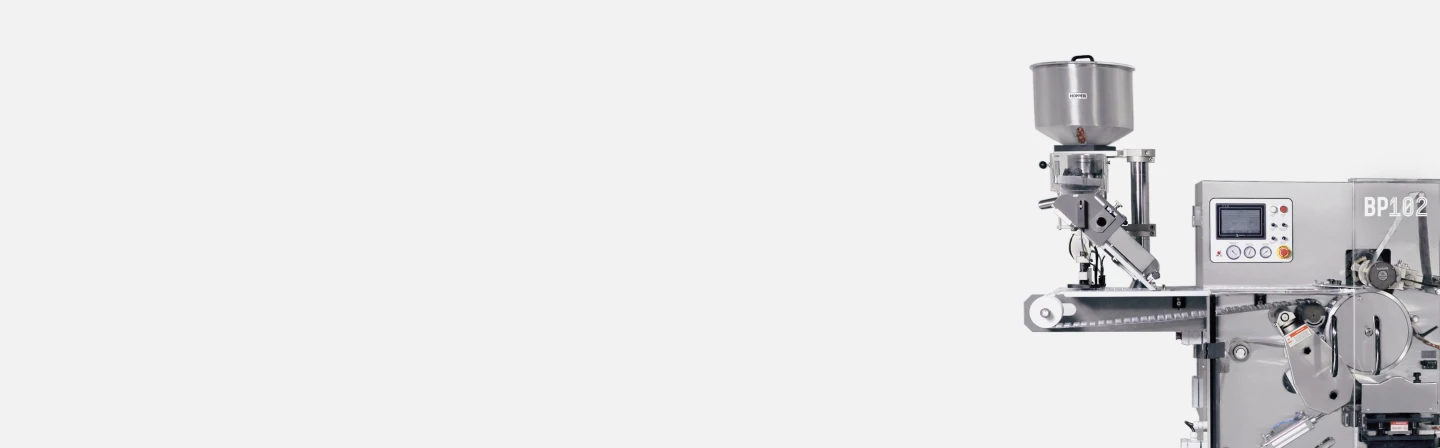

About the BP 102

A compact, high-performance, cost-effective blister-packaging machine with robust rotary-forming and sealing technology. Producing high-quality thermoform blisters efficiently, BP 102 is perfect for the cost-conscious pharmaceutical industry and features unique single-drum technology for full operational flexibility.

Applications

Blister packaging of solid dosage products for small- to mid-scale production

| Features | Benefits | |

|---|---|---|

A single drum for forming and sealing | Better blister quality, with fewer format parts | |

Available in single and twin-station configurations | Flexibility for a wide range of blister requirements | |

Compact footprint | Can be installed easily in limited space | |

Easy-fit punch-tool assembly | Faster, easier and more reassuring changeovers |

Features & Benefits

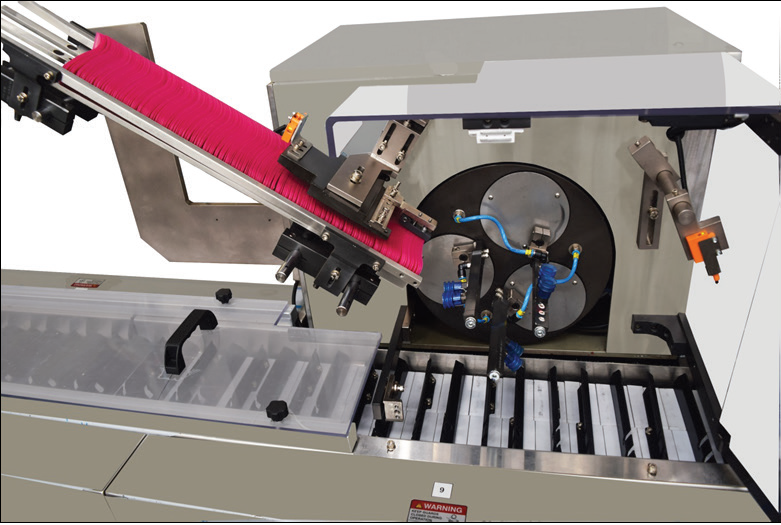

A single drum for forming and sealing

Better blister quality, with fewer format parts

Available in single and twin-station configurations

Flexibility for a wide range of blister requirements

Compact footprint

Can be installed easily in limited space

Easy-fit punch-tool assembly

Faster, easier and more reassuring changeovers

Technical specification

| Output | Up to 4.5 m/min (Thermoforming) |

| Forming depth | Up to 12 mm (Thermoforming) |

| Maximum blister size | 200 mm x 100 mm |

| Forming materials | PVC, PVC/PVdC, Triplex (PVC/PE/PVdC) |

| Lidding materials | Push-through foil, child-resistant foil, peelable (paper) |

You can’t have healthy people without a healthy planet.

BACK TO ALL PRODUCTS

BACK TO ALL PRODUCTS