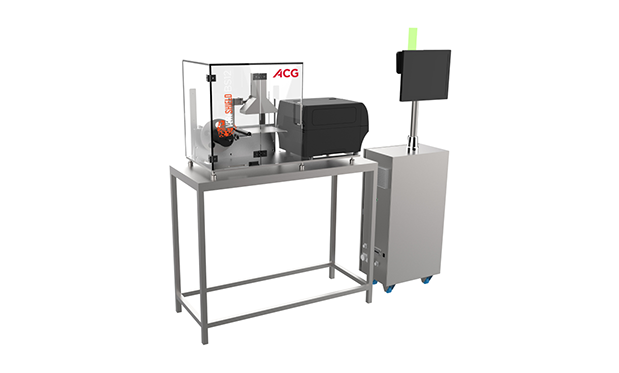

About the QUALISHIELD CV51

The QUALISHIELD CV series is a high-speed, high-resolution, multi-colour, camera-based solution for inspection of a variety of data, including barcodes, pharmacodes, 2D codes, batch details, and much more – on inspection media such as cartons, labels, leaflets, foils, tubes, and many others. You can install it on any carton- or blister-packing machine, and it’s retrofittable to a wide range of bottling, cartoning and manual packaging lines. The CV series can be integrated with various types of cameras, based on different needs.

QUALISHIELD CV51 is an online camera-based inspection system you can mount on any labelling, cartoning or blister-packaging machine. It accurately and reliably captures details such as batch and expiry, 1D barcodes, 2D datamatrix codes, pharma codes – on inspection media including cartons, labels, foils, leaflets, tubes, and many others.

Applications

Inspection of barcode, pharmacode and OCR/OCV inspection on carton, leaflet and booklet

| Features | Benefits | |

|---|---|---|

| Inspects contents of cartons, labels, foils, leaflets and tubes using a modular software architecture |  |

One hardware and software solution for multiple uses in a single setup |

| Supports printing in continuous inkjet, thermal inkjet, hot stamping and thermal transfer overprinters (TTOs) |  |

Compatibility with a wide range of industrial printers |

| A plug-and-play installation that supports all types of PLC rejection mechanism protocols |  |

Accurately and reliably captures details on labels such as batch and expiry, 1D barcodes, 2D datamatrix codes, pharmacodes |

| Fast and easy plug-and-play installation |  |

Can be integrated with continuous or intermittent machines |

Features & Benefits

Technical specifications

| FOV (Field of view) | 60mm x 40mm |

| Number of cameras | 2 |

| Products that can be inspected | Carton, leaflet, label, vial |

| Maximum speed* | 300 products/min |

*Speed can vary according to the number of camera configurations, image saves, camera configurations (one or more), and product size. | |

Also Available In

|