About the QUEST FB II X•ONE

Supreme safety with ultimate versatility – that’s what you get with the FBC X•ONE series developed at our Design Centre in Mülheim, Germany. While you can use it for diverse applications, including drying, top-spray granulation and Wurster coating, its cutting-edge design and features don’t compromise process or operator safety. In short, you get the very best outcomes and unbeatable protection.

Combining great design with ergonomics, QUEST FB II X•ONE is a safe, versatile lab machine with multiple applications. Its capability and performance across drying, granulation, Wurster coating and rotor granulation cover the full range of R&D-scale studies.

Applications

Drying, wet granulation, Wurster coating and rotor granulation

| Features | Benefits | |

|---|---|---|

A 12-bar pressure shock resistant system featuring the Maximum Operator Safety Technology (MOST™) concept approved by ATEX and certified by FSA |

|

No mechanical deformation caused by pressure-shock

Far safer for the environment, thanks to a non-vented, fully contained design |

Swivel filter housing |

|

A versatile and portable system for drying, single-pot granulation and Wurster coating

Quick and easy to install and use anywhere in your lab

A single system for diverse applications |

Unique filter change system |

|

Reduces dust emissions to a minimum, and ensures operators’ safety and ease of use |

Slide-in/slide-out process inserts |

|

Easy charging and discharging |

Four process inserts |

|

Handle varied batch sizes and multiple applications (drying, granulation, Wurster coating and rotor granulation) with greater operational flexibility |

Features & Benefits

A 12-bar pressure shock resistant system featuring the Maximum Operator Safety Technology (MOST™) concept approved by ATEX and certified by FSA

No mechanical deformation caused by pressure-shock

Far safer for the environment, thanks to a non-vented, fully contained design

Swivel filter housing

A versatile and portable system for drying, single-pot granulation and Wurster coating

Quick and easy to install and use anywhere in your lab

A single system for diverse applications

Unique filter change system

Reduces dust emissions to a minimum, and ensures operators’ safety and ease of use

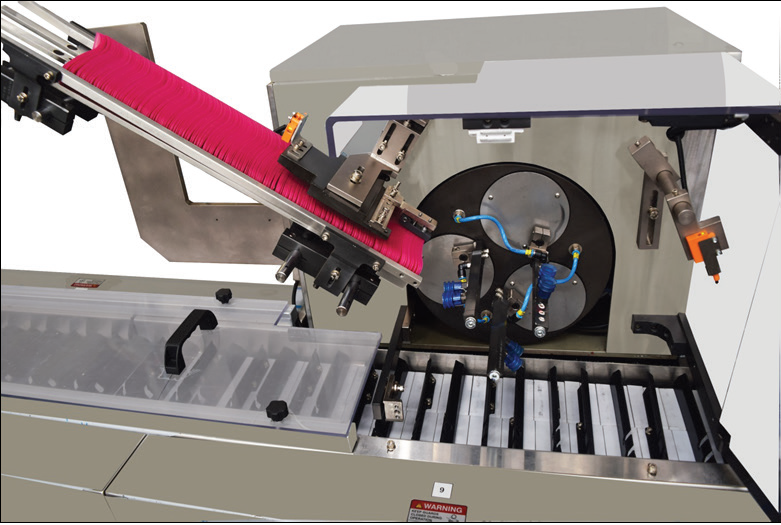

Slide-in/slide-out process inserts

Easy charging and discharging

Four process inserts

Handle varied batch sizes and multiple applications (drying, granulation, Wurster coating and rotor granulation) with greater operational flexibility

Technical specifications

| Top-spray granulation | |||||

| Bowl size | 3 l | 6 l | 9 l | 12 l | |

Working volume | Min | 0.6 l | 1.2 l | 1.8 l | 2.4 l |

| Max | 3 l | 6 l | 9 l | 12 l | |

| Wurster coating | ||||

| Bowl size | 3 l | 6 l | 9 l | |

Working volume | Min | 0.6 l | 1.2 l | 1.8 l |

| Max | 2 l | 4 l | 8 l | |

Also Available In

|

Related products

Always getting better at helping make people better.